Machine safety – Key topic at METAV 2020

Machine safety – Key topic at METAV 2020

Machine safety – Key topic at METAV 2020

VDMA standard sheet clarifies "Safety requirements for clamping devices in machines". Safety in machine handling will feature prominently in various forums at METAV 2020. One of the issues being discussed in Düsseldorf will be the new VDMA Standard Sheet 34192 which improves cooperation between the ...

Read More

Protecting machine tools from cyber attacks

Protecting machine tools from cyber attacks

Protecting machine tools from cyber attacks

Data security is gaining in importance as Industry 4.0 takes shape. Automation, cloud applications and globally networked machines and components play key roles when it comes to shielding systems from external threats.

Read More

Digital yet sustainable – How so?

Digital yet sustainable – How so?

Digital yet sustainable – How so?

Industrial processes can either be digital or sustainable – at least that is the belief of many who have not yet given the issues involved the consideration they deserve. But the VDMA Technology Forum at EMO Hannover will be proving the opposite: applied sensibly and judiciously, digitalisation can ...

Read More

Cobots – Successful collaboration between man and robot

Cobots – Successful collaboration between man and robot

Cobots – Successful collaboration between man and robot

Robotics and automation are among the key technologies for ensuring lasting international success. Cobots interact directly with humans and give manufacturing companies a competitive edge in the market. At EMO Hannover 2019, trade visitors will find countless automation solutions and collaborative r...

Read More

Amendate: smart software at EMO Hannover

Amendate: smart software at EMO Hannover

Amendate: smart software at EMO Hannover

Relieving engineers of tiresome routines and unleashing their creativity: the goal of Amendate GmbH from Paderborn is to take additive manufacturing to the next level. The new company is planning to have its latest piece of software ready for market in time for the EMO Hannover trade fair where it w...

Read More

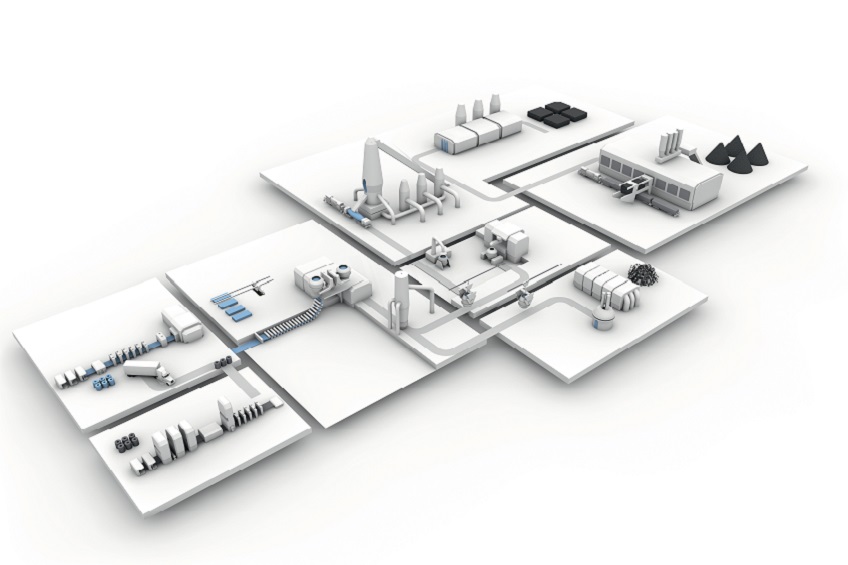

Lightweight construction is key technology for global sustainability

Lightweight construction is key technology for global sustainability

Lightweight construction is key technology for global sustainability

Intelligent lightweight solutions are increasingly gaining ground in machine tool construction. The main focuses are on new geometries and materials as well as simulation and 3D printing. Exhibitors at EMO Hannover will be showing how products can be designed and manufactured to meet lightweight and...

Read More

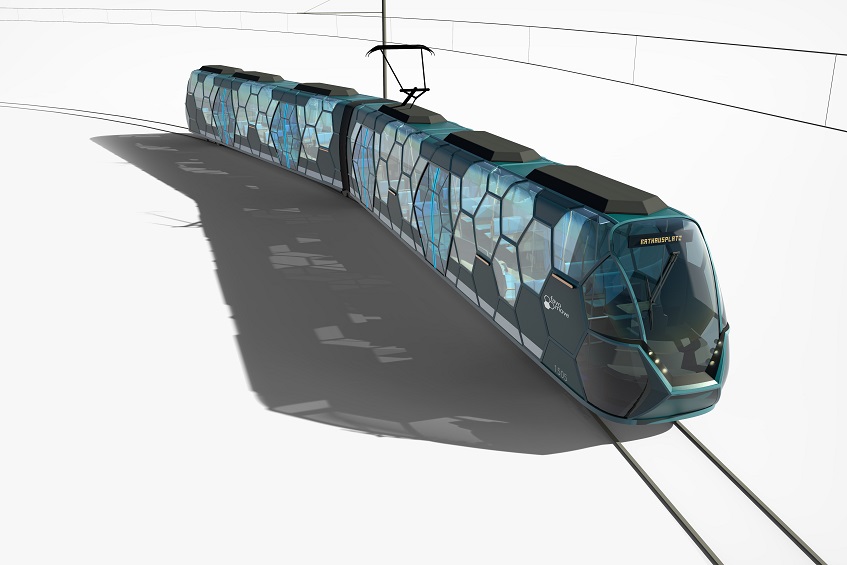

Engineering inspired by nature

Engineering inspired by nature

Engineering inspired by nature

Frankfurt am Main, 20. May 2019 – There is an established tradition of young entrepreneurs presenting their new business models at EMO Hannover. CellCore, a company founded by Andreas Krüger and two of his colleagues at the end of 2016, is one of the exhibitors on the joint start-up stand supported ...

Read More

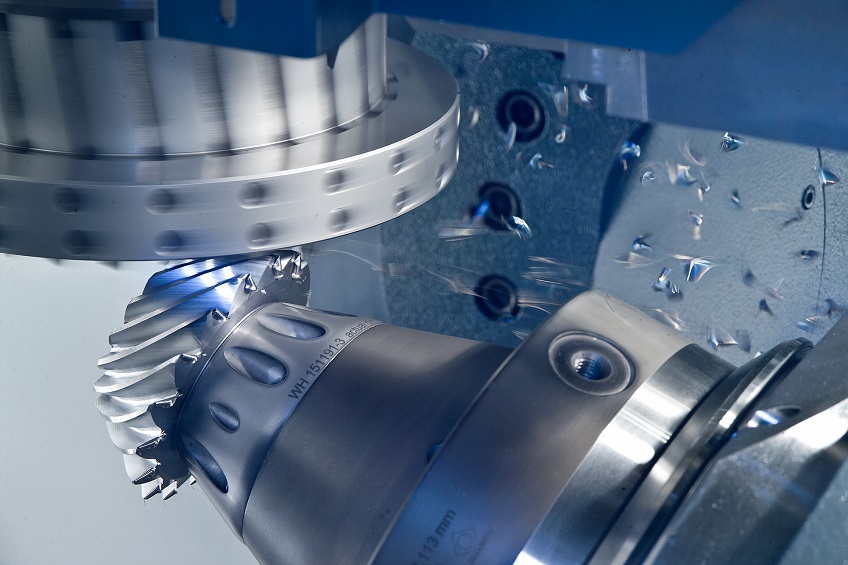

Manufacturers making increased use of dry machining and MQL

Manufacturers making increased use of dry machining and MQL

Manufacturers making increased use of dry machining and MQL

Should we continue with classic machining and coolant lubricants, or do dry machining and minimum quantity lubrication (MQL) represent viable alternatives? From a technology point of view, it is important to consider material properties and machine performance, but plant costs, energy and health asp...

Read More

Dry machining and MQL conquering more and more applications

Dry machining and MQL conquering more and more applications

Dry machining and MQL conquering more and more applications

Production managers in manufacturing often have to ask themselves: should we continue with conventional machining and coolant lubricants, or do dry machining or minimum quantity lubrication (MQL) represent viable alternatives? Several factors influence this decision. In Part 1 of this two-part serie...

Read More

Doomed to fail without AI?

Doomed to fail without AI?

Doomed to fail without AI?

The headline is intentionally provocative. According to a 2018 study by Boston Consulting, China, Japan and the USA have been upgrading their artificial intelligence (AI) systems for some time now, meaning that Europe urgently needs to take action. Prof. Jörg Krüger, Head of the Industrial Automatio...

Read More