Press Photos and Picture Database

So as to support your reporting on VDW and the German machine tool industry, we will be pleased to make available to you pictures and photos for editorial use. Please make sure you always give the correct source attribution(s). We would very much appreciate it if after publication you could send us a link or a courtesy copy of your coverage for our archives.

You will always find press material for covering our NORTEC and EMO Hannover trade fairs on the website of the fair in question. For photos, audio contributions and videos on EMO Hannover, please follow this link. You can retrieve press photos on NORTEC here.

4_Reges Interesse vor WZM_0512200006_0011

3_Blick in Halle 17_0512200008_0015

2_Eingang_2. EMO_0512200008_0043

1_Briefmarke_1. EMO_Paris__bild_Poster-1975_2024-09-06

portrait_mike dreher_2024-09-09

portrait_jochen arnold_2024-09-09

portrait_heering_2024-09-09

portrait_ryan martin_2024-09-09

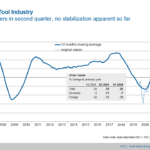

gra_pm_ae_2024 Q2_eng_2024-08-13

Dr. Markus Heering

Twitter Banner MTI

EMO Hannover 2023

Carl Martin Welcker

Weber Wolfram

Franz-Xaver_Bernhard_Portrait_5_2021_04_ohne Logo_quer

bild_heller_schmidt_2024-07-29