Additive Manufacturing Area at EMO Hannover 2023 showcasing production technology synergies

AM process chain has many areas of overlap with subtractive manufacturing: many additively manufactured components still need to be machined before they can be used.

EMO Hannover, the world’s leading trade fair for production technology, will be presenting the Additive Manufacturing Area from 18 to 23 September 2023 on stand G22 in Hall 9. “Additive manufacturing is now a firm fixture at EMO Hannover,” says Dr. Markus Heering, Managing Director of the Additive Manufacturing (AM) association within VDMA. “This is because the AM process chain has many areas of overlap with subtractive manufacturing: many additively manufactured components still need to be machined before they can be used. Only then do the advantages of additively manufactured components – such as lightweight grippers, near-contour cooled tools, on-demand spare parts and much more – come into play,” continues Heering. That is why the Additive Manufacturing Area at EMO is the place to be for all trade visitors interested in the latest developments in industrial 3D printing – either because they wish to integrate it into their production, or because it can be used to turn their new product concepts into reality.

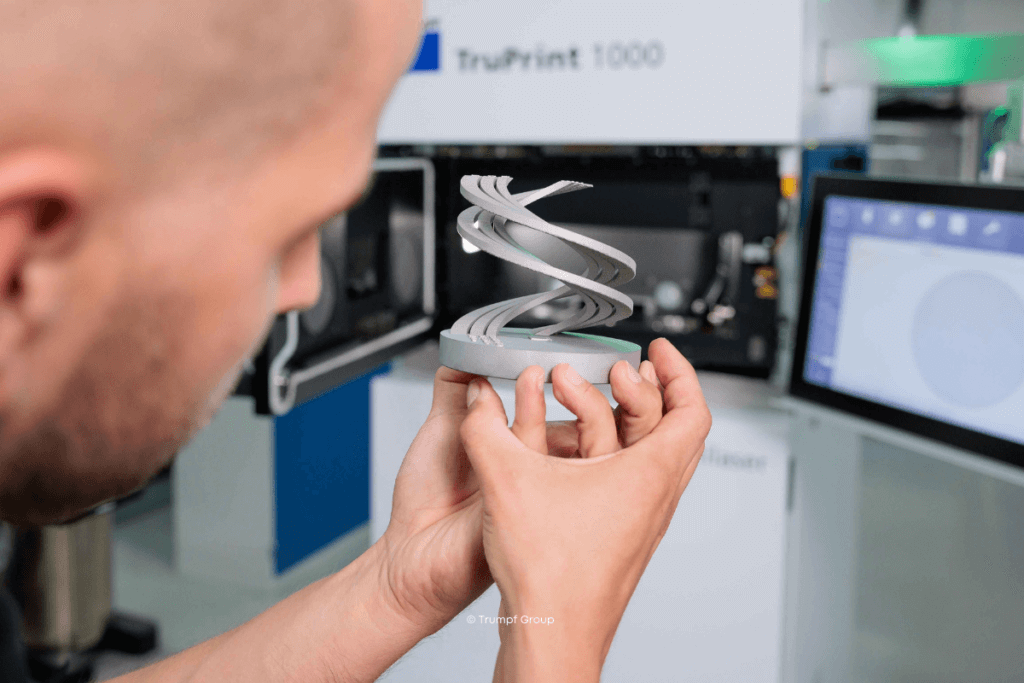

Nine companies – Additive Industries, Daimler Buses – EvoBus, Hamuel Maschinenbau, Q.Big 3D, Schoeller-Bleckmann Oilfield Technology, Trumpf Laser- und Systemtechnik, VDMA Association AM, JEOL and Carl Zeiss Industrielle Messtechnik – will be showcasing innovative concepts such as direct and indirect 3D printing technologies, materials, and Rapid Product Development (RPD). They will be explaining how additive manufacturing can be integrated into the production process.

Gabriel Pankow, spokesperson for Trumpf Laser- und Systemtechnik, Dietzingen, Germany, says: “The focus at EMO is on production technology, and additive manufacturing is an important part of that. That’s why we’re taking part in the Additive Manufacturing Area. We’ll be using various components to demonstrate the great potential of 3D printing for tool and mold making, for example. User benefits can be found in fields such as prototype development and tool weight reduction. Tool manufacturers can also use additive manufacturing to integrate filigree internal cooling channels into their tools. These enable precise cooling of the tool.”

“Layering technologies have become a distinct industrial manufacturing process and are now being used with increasing success in many fields of application. This innovative process holds great potential – and is just waiting to be discovered at EMO,” adds Markus Heering. As examples, he cites design freedom, flexibility and services – aspects which are useful not only for machine tools. Oliver Friz, Managing Director of Q.Big 3D in Aalen, Germany, believes that 3D printing holds a great deal of potential which is far from exhausted. “Larger-scale 3D printing has not yet caught on in the market in the way that the printing of smaller components has. At EMO, we will be displaying engineering solutions for cladding parts, tanks, and measuring and assembly fixtures, for instance. Exploiting all the geometric freedom offered by 3D printing, our machine can produce larger components faster, more cheaply and in more environmentally friendly ways than conventional manufacturing methods.”

For Kartik Rao, Strategic Marketing Director at Additive Industries from the Netherlands, the main focus is on AM automation. “Additive Industries is using large construction sizes, robustness and productivity to redefine the business case for aerospace, automotive, energy and high-tech equipment. At EMO, we will be showing how the automation integrated into our printers improves the cost structure for parts production and offers even greater design freedom in additive metal manufacturing.” Andreas Tietz, Global Head of Sales at Zeiss AM Technology in Oberkochen, Germany, emphasizes the importance of high quality, including in 3D printing. “Automotive, aerospace, consumer goods and medical device manufacturers turn to additive manufacturing when they want to increase production efficiency, customize parts, or achieve a faster time to market. However, these advantages can only be exploited if the required quality is guaranteed. At EMO we are offering many products and solutions aimed at improving quality, analyzing the causes of defects, pushing long-term process improvements and setting standards for series production in the future.”

These three companies represent prime examples of what visitors can expect in the Additive Manufacturing Area. Interested parties can also obtain detailed information on the highlights of the Additive Manufacturing Area at the Innovation Forum in Hall 9. There will also be an international conference on additive manufacturing on 20 September 2023 in Room 3A at the Convention Center, hosted by the European machine tool association Cecimo.