Digitalisation is the EMO’s leitmotif

If Industry 4.0 were merely the generic term for a new photo or TV application, the publicity slogan for the EMO Hannover 2017 might perhaps be “Industry 4.0 – the wish list” or “Industrial Internet of Things – because I’m not stupid”. The fair’s keynote theme of “Connecting systems for intelligent production” is more complex, but has nonetheless been well received. This has been confirmed by a survey among EMO exhibitors on digital transformation.

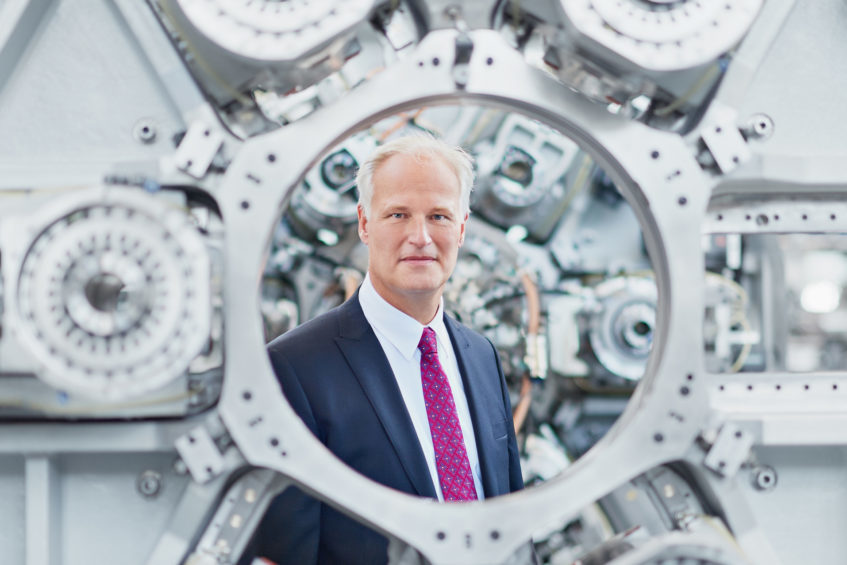

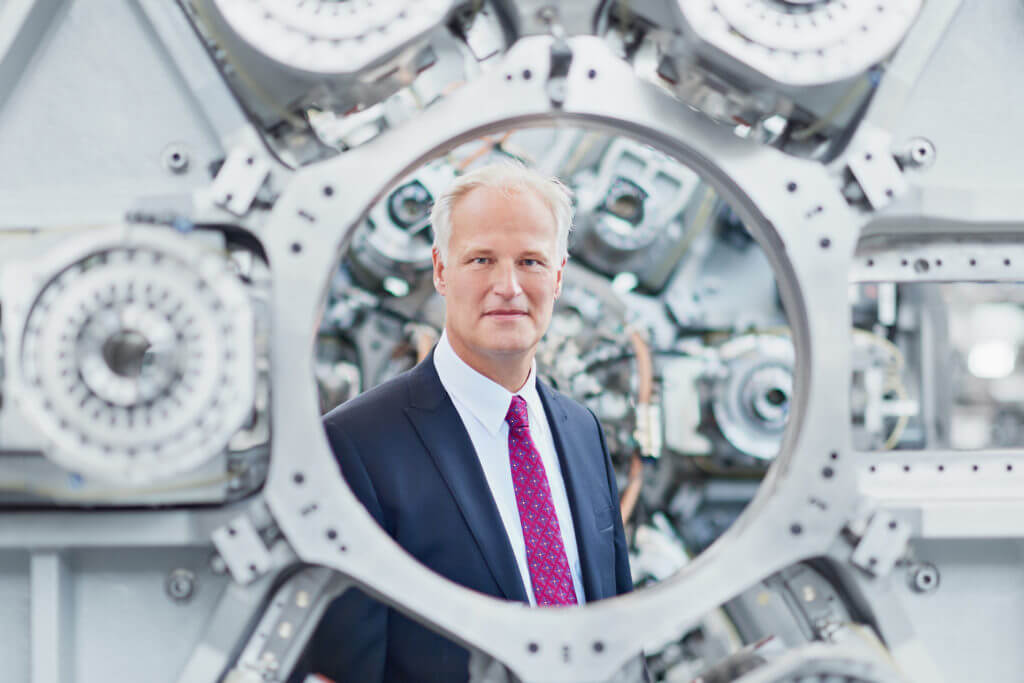

“The paramount tasks for manufacturers and users of machine tools are entailed by digitalisation,” explains the EMO’s General Commissioner and VDMA President, Carl Martin Welcker. “It’s precisely this issue that’s addressed by this year’s EMO Hannover.” He sees the fair as contributing towards overcoming obstacles in the thrust for digital transformation. He also refers to Industry 4.0 as a mindset: encouraging staff to come up with ideas on how they can put Industry 4.0 into shop-floor practice. His company, too, Alfred H. Schütte GmbH & Co. KG from Cologne, is actively engaged in the quest for digital transformation. It began to address the ramifications of Industry 4.0 more than two years ago. On a dedicated stand at the EMO, the company will be demonstrating how thanks to their open interfaces automated machines can be networked in conformity with the OPC-UA standard. “We shall, for example, be demonstrating how machine data can be shifted onto the net, to be retrieved later on from far away using an app,” explains Schütte’s Managing Director Carl Martin Welcker. “This offers our customers an option for visualising and monitoring the ongoing status, and analysing production data, as a basis for initiating maintenance work, for example.”

A continual development process

“When it comes to Industry 4.0, we’re engaged in a continual design enhancement process,” comments Klaus Eberts, Department Head Key Accounts at Grob-Werke GmbH & Co. KG, Mindelheim. “Most of the development work is handled by the internal Industry 4.0 Department.” Products already developed, like Grob4Analyze or Grob4Pilot, are designed to upgrade production efficacy and availability. The next projects, which will deal with machine learning, virtual worlds, plus energy-efficiency and resource-economy, are already being planned.

Not only for itself, but also for customers and other partners, the company has developed its own software package called Grob-Net4Industry featuring ten individual modules, designed to digitalise and network the production lines involved. But it’s not exclusively the technology, but also the ergonomics that are playing a progressively more important role in Industry 4.0. Grob will here be showcasing its special “Grob4Pilot” HMI (Human-Machine Interface) operator control concept. A multi-functional operator interface and support from specifically conceived applications enable users to run paperless production and benefit from intuitive, human-engineered machine operator control. “Thanks to revolutionary input devices, the machine operator will perceive a new level in terms of user prompting and control capabilities,” says Markus Frank, Department Head Grob-Net4Industry. “The innovative Grob4Pilot product has been jointly developed in conjunction with application technicians, operators, designers and software engineers. The motto adopted for the development work was usability meets efficiency.”

Trend-scouting for e-mobility, lightweight construction and Industry 4.0

The machinery manufacturer Gebr. Heller Maschinenfabrik GmbH from Nürtingen has been addressing the issue of Industry 4.0 ever since 2010 – i.e. long before the currently ubiquitous term was actually coined. For this purpose, the company had set up a separate R&D department called Development New Business & Technologies. The advantage of a specialised department like this is that it scrutinises new technologies in order to then develop future lines of business from them. The principal focus here has for seven years been purposeful trend-scouting for the issues of reducing carbon dioxide emissions and consumption levels for internal combustion engines, e-mobility, lightweight construction and Industry 4.0. Key aspects of digitalisation include supplementary machine functionalities, services on demand, and expanded service support options.

The aim is to increase productivity

Bernd Zapf, Head of Development New Business & Technologies, explains the approach involved: “Under the aegis of Heller4Industry, we synergise all activities in connection with Industry 4.0 and digitalisation in the process chain. One of our goals in the field of metalworking is to increase productivity still further and thus create added value for customers. Upgrading overall equipment effectiveness (OEE) – which we see as the product of the availability, productivity and quality variables – will succeed when the machine is harmonised with the boundary conditions involved.”

For Heller, though, Industry 4.0 also means improving operator control: for this purpose, they have created a simple, new operator-oriented user interface, which provides the operator concerned with touch functions that are otherwise typical for smartphones or tablets. Another I4.0 building block is the Heller Services Interface, which renders manufacturing and maintenance processes transparent. The module constitutes the basis for analyses and statistics, and supports its users in reducing machine downtimes. The visualisation capability helps maintenance staff to obtain selective information on the status of axles, spindles, and other assemblies: it uses predictive maintenance to determine the current wear-and-tear status, so as then to initiate preventive measures intended to avoid unplanned standstills. The Heller4Performance module is designed to enhance processes and performance, and for this purpose it synchronously transfers real-time data to the intranet, which are then analysed and visualised externally on a cloud platform, thus facilitating the adoption of Industry 4.0.

The tool and its digital twin

“The thrust for Industry 4.0 will prove to be a dead end without the data from the manufacturing aids,” comments Dr.-Ing. Götz Marczinski, Managing Director of Cimsource GmbH from Aachen. “The ability to supply these data and to make proper use of them will in future be essential if you wish to remain competitive.” One of the most important manufacturing aids for metal-cutting applications is indubitably the tool involved. In terms of data transparency, however, Industry 4.0 stands and falls with the digital image of the real tool. What is called the digital twin with all relevant data helps when simulating a metal-cutting function, when “equipping” a virtual machine tool, or when digitalising the value added chain in a factory (supply chain).

The mechanical engineer and graduate of RWTH Aachen University was inspired by the institution’s concept of the internet of production and the concomitant idea of a harmonised, consistent data structure (keyword: single source of truth). As a kind of machining Google, the firm has created a platform called ToolsUnited, whose latest functions they will be showcasing at the EMO Hannover. These include an option for tool manufacturers enabling them to operate a portal of their own, via which they can communicate directly with their vendors.

“We see ourselves as a dealer for the internet of production, who helps tool manufacturers with editing data and creating digital twins, which we then merge in a standard format,” says Götz Marczinski. “In this way, the end-user obtains a single source.” Users of ToolsUnited can find a suitable web-shop with the aid of the database, and browse it to find their regional vendors. But because ToolsUnited is not a commercial platform, the purchases involved are handled through the web-shops concerned.

But Cimsource aims to go one step further when it comes to the digital twin. Together with the Fraunhofer Institute for Microelectronic Circuits and Systems (IMS) from Duisburg and the Heinz-Nixdorf Institute in Paderborn, the firm intends to ensure that key statistics from the metal-cutting processes can be more dependably acquired. “The data from the machine’s control system are inputted, and can be appropriately assigned to the relevant tool by means of an identification number,” explains the Managing Director. However, these data always have to be available directly in connection with the tool, i.e. even after reprocessing the tool, e.g. regrinding. For this purpose, in turn, the data must not be stored in the tool itself; a reference has to be set up to an appropriate lifecycle file in the cloud.

Cimsource is now developing a new technology based on radio frequency identification (RFID). The concept involves a minuscule chip with a radio antenna that transmits and receives the job and tool data concerned. The solution stands and falls with a technology that integrates the chip into the tool during production in such a way that it still functions even after reprocessing. “In this way, a swarm of data-collecting tools could be implemented, which generate big data for the ToolsUnited platform, in which with the aid of data-mining algorithms solutions for metal-cutting jobs are then created,” explains Götz Marczinski. “But we’re still searching primarily for a method of applying machine-readable ident numbers to the tools.”

Digital metrology upgrades convenience at the workplace

But Industry 4.0 also means a smart factory, in which fast, automatic, operator-friendly metrology has top priority: the bandwidth ranges from manual measuring instruments with radio transmission all the way through to automated, electronically controlled measuring machines with robot loading. “Our digital outside micrometers, calipers and dial gauges render the daily work routines in the quality assurance of production plants significantly more convenient,” says Utz Wolters, Head of Sectoral and Applications Marketing at Mahr GmbH, Göttingen. “These measuring instruments feature the operator-friendly integrated wireless system, which increases the user’s freedom of movement.” This means, he continues, that for measurements at processing machines, for example, or in the case of sizeable workpieces the inconvenience of data cables is eliminated. Mahr possesses the European patent for the integrated radio link.

The option for radio transmission of data, moreover, he adds, simplifies the acquisition and documentation of measured data. These data can be sent at the touch of a button at the measuring instruments concerned or in response to remote control commands to a radio receiver at the computer, to suit the task concerned. Mahr will, for instance, be demonstrating at the EMO Hannover how production metrology functions in conjunction with Industry 4.0, with the global premiere of their new ultra-high-performance “radio outside micrometer”. Visitors will also be able to learn more about these and other innovations themed around the digital transformation at the numerous presentations – e.g. at the VDMA’s Innovative Solutions for Industry 4.0 forum (Hall 4, Stand D44) or the forum under the aegis of the Special Show in the Industry 4.0 area (Hall 25, Stand B60).

VDMA forum at the EMO 2017: innovative solutions for Industry 4.0

From 19 to 21 September, VDMA member companies and partners from the research community will on the VDMA’s stand at the EMO Hannover in 30 short presentations be spotlighting innovative ideas and products relating to Industry 4.0. The focus here will be on presentations dealing with specific technical implementations from the fields of high-precision tools, metrological and testing equipment, research and exchange of tool data. Visitors will learn how intelligent clamping systems work, and how by networking tools and software production processes can be simulated, tool life-cycles monitored, and costs downsized.