How companies can capitalize on their valuable data

More and more companies are using detailed process data from digitalized production, or even artificial intelligence, to enhance their own internal production. If used effectively, such massed quantities of data represent a raw material that can be used to add significantly greater value.

Data-driven business models are still the exception rather than the rule, however. In most cases, it is large corporations like Rolls Royce that are venturing into such new forms of business. They include “sharing economy” models in which pay-per-use pricing models are applied. Rolls Royce, for example, no longer just sells turbines, it also rents them out. The customer then only pays for the running time. This represents an important step towards more sustainable manufacturing and the circular economy.

Securing a place in the platform economy

New core businesses can also be developed in conjunction with digital platforms. These are online marketplaces where B2C (but increasingly also B2B) companies network with each other and create their own digital ecosystems. One example of this is the Adamos platform founded by numerous major companies from the mechanical and plant engineering sector. It is difficult to overestimate how important it is for the German industry to open itself up to this digital platform economy if it wishes to remain competitive internationally.

But what is the best way of doing so? What distinguishes conventional from digital business models? What tools are required by companies that are looking to generate data-based value? And how can small and medium-sized enterprises use – and monetize – their data for innovative products and services?

In the May edition of the monthly “Let’s Talk Science” live webinar at EMO Hannover, experts from the Institute of Production Management, Technology and Machine Tools (PTW) at TU Darmstadt answer the question: “How can data be used data for new business models?” For several years now, the researchers have been working on numerous industry-related research projects aimed at integrating AI, and examining the related economic issues for industry.

Let the experts show you how to create new value using this hitherto neglected raw material. Put your questions to them at

Let’s Talk Science, 31 May 2023, 11:30 am

Registration

https://emo-hannover.de/lets-talk-science

Presenters

Prof. Joachim Metternich, Head of the Institute of Production Management, Technology and Machine Tools (PTW) at TU Darmstadt.

Felix Hoffmann, Head of Research in Production Management at the Institute of Production Management, Technology and Machine Tools (PTW) at TU Darmstadt

Downloads

Pictures

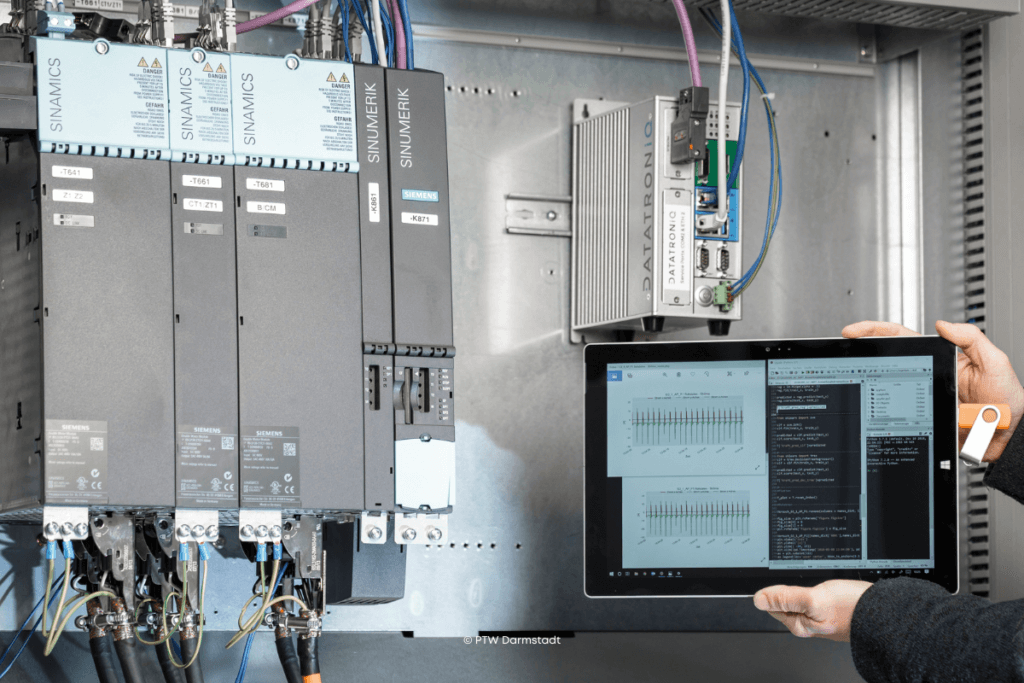

Picture 1: KI-basierte Überwachung einer Werkzeugmaschine in der Produktion, Quelle: PTW Darmstadt

Picture 2: Prof. Joachim Metternich, Leiter des Instituts für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW) der TU Darmstadt

Picture 3: Felix Hoffmann, Forschungsleiter Produktionsmanagement, Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW) der TU Darmstadt