Hybrid manufacturing processes for increased competitiveness

Combining different manufacturing processes often pays dividends for manufacturing companies. This also applies to grinding and precision machining technologies. Significant increases in productivity can be achieved if modern automation and digitalization concepts are added, resulting in greater competitiveness.

GrindingHub 2022 presenting effective combinations for grinding technology

Combining different manufacturing processes often pays dividends for manufacturing companies. This also applies to grinding and precision machining technologies. Significant increases in productivity can be achieved if modern automation and digitalization concepts are added, resulting in greater competitiveness. GrindingHub, the internationally oriented trade fair for grinding technology, will provide a compact overview of the market for production technologies in this challenging environment from May 17 to 20 in Stuttgart.

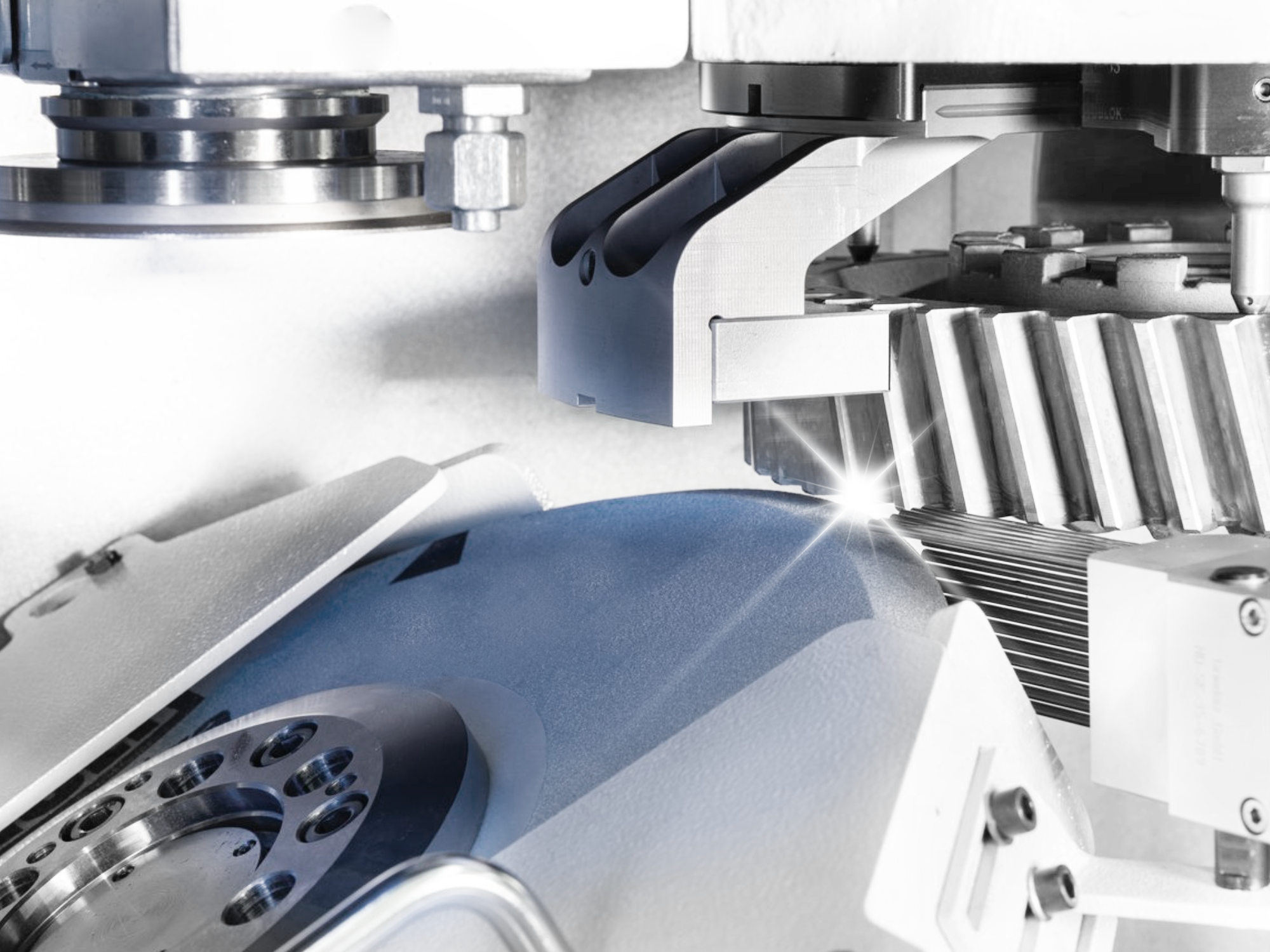

Hybrid machines for numerous manufacturing solutions

Large unit quantities, enormous cost pressure and precise production processes are among the major challenges facing gear manufacturers. And these are set to increase in the future, because the changes in the automotive industry are having a strong impact on this sector. The aim is to produce significantly more transmission variants in the future. How are companies meeting this challenge? The machine manufacturer Emag GmbH & Co. KG, based in Salach in south-west Germany, has provided an impressive answer to this question with its newly developed series. Its great strength is that by combining grinding, turning and other processes (including automation) it permits numerous manufacturing solutions to be carried out. It can thus take care of the complete machining of transmission components.

The company has added another machine to its portfolio: it is larger and designed for components up to 350 mm in diameter. For the first time it also offers the option of integrating a grinding spindle with NC swivel axis. This can include a cylindrical grinding wheel, for example, that can be used to grind internal bores. “We’re talking here about manufacturing processes with smaller batch sizes, which inevitably include many changeover processes,” explains Markus Isgro from Emag’s communications department. “In such cases, it’s of course useful if a range of different grinding spindles are included in the machine from the outset. Sufficient room is set aside in the workspace for this purpose. It can then be set up for all tasks.” This means that the conventional hard machining of gear wheels and many other chuck parts with an internal taper can be performed in the machine tool itself – from hard turning of the plane surfaces to rough turning of the bore and the external synchronizer cone to finish off the contours. “Emag will be happy to answer any questions visitors may have about hybrid machining technologies at GrindingHub 2022,” says Isgro.

Improved surface fidelity and cost-effectiveness

The advance of additive manufacturing processes is inevitable, as they yield a whole range of impressive advantages. In addition to increasing productivity by enabling flexible production and eliminating the need for conventional toolmaking, the large variety of geometric design possibilities also allows the processing of highly complex components. The high degree of flexibility ensures that small to medium quantities can now be produced using industrial 3D printing. However, there is still need for post-processing in many cases. Depending on the component and process, it may be necessary to remove any auxiliary and support structures used during the additive process. Otherwise, surface finishing operations such as milling, grinding or superfinishing and component inspection have to be performed. Other processes such as component cleaning and marking are possible, as is the entire handling process, including sorting and packaging.

For greater efficiency, however, it is necessary to incorporate both additive and subtractive manufacturing in a hybrid system. The post-processing requirements need to be taken into account from the outset when creating the 3D model. Applying too much material leads to increased costs, whereas too little makes post-processing of the workpiece difficult or impossible. Ideally, there is direct data integration throughout the process chain. In practice, this means that the processes are precisely coordinated and are carried out without any need for further workpiece handling. Robot-assisted and automated solutions such as an innovative manufacturing cell for automated surface finishing by Supfina Grieshaber GmbH & Co. KG, based in Wolfach in the Black Forest, are designed for precisely this purpose. Processes can be flexibly combined and seamlessly integrated into production with just one setup. This yields both high surface fidelity and improved cost effectiveness. The Supfina specialists will also be exhibiting in Stuttgart and will be happy to provide further information.

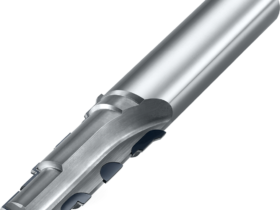

Highly efficient tool production based on combination machining

Increasingly complex and precise tools made of different materials are currently being developed which pose challenges for the manufacture of tool grinding machines. “Not all materials or combinations can be fully processed simply by grinding alone,” explains Siegfried Hegele, Applications Product Manager at Walter Maschinenbau GmbH, Tübingen. “Technologies such as EDM or lasers, including measurement systems, are also required. As system and solution providers, Walter and Ewag are single-source suppliers of solutions for all tool machining requirements. These, too, will be showcased at GrindingHub.”

Manufacturing a PCD (polycrystalline diamond) tipped milling tool, for example, involves several steps. Here, a sintered carbide tool is first subjected to cylindrical grinding. The chip spaces are then ground. A machine with high spindle power is required in order to perform these operations effectively. The next step involves grinding the plate seats in the carbide bodies. Unlike at the beginning, high speeds are required here because of the small grinding pins. Before soldering can take place, it first needs to be checked whether the tolerances have been observed during the grinding processes. Ideally, this is done using an automatic CNC measuring machine. The next step is to solder the PCD plates pre-cut from a PCD circular bed into the plate seats. Here, the polycrystalline diamond is briefly heated to near graphitization temperature. After that, the tool must be cleaned and a decision must be made as to which technology is best suited for machining the PCD. Here, combined machining involving different technologies such as grinding and EDM can yield significant advantages. A final measurement is then made for quality control.

Reduced times, improved productivity and quality

Combining manufacturing processes also opens up new potential in production. The classic motivation for simultaneous multiple machining of a workpiece within a machine containing several spindles, for example, is to reduce the cycle time. In principle, however, the machines required for this involve high investment costs and are only economical for large quantities due to their low flexibility. Furthermore, hybrid machining on a single machine can help raise quality, productivity and process reliability levels, as fewer errors arise from the clamping or transporting of components.

In addition to combining grinding technology and cutting processes with a geometrically determined cutting edge, the interaction of different grinding processes within a single machine is also highly useful. In the case of gears, for example, special finishing processes are increasingly being used to carry out the machining within the grinding machine itself. Until now, finishing has often required additional equipment (for vibratory grinding for example) which is often only available from external service providers. “In the past, when gears were manufactured in the automotive industry, the high costs involved meant that they were rarely reworked. Hybrid tool concepts are now increasingly being used here, enabling both grinding and finishing operations to be carried out,” says Prof. Eckart Uhlmannhead of the Fraunhofer Institute for Production Systems and Design Technology (IPK) in Berlin. He is also a member of the WGP (German Academic Association for Production Technology), an association of leading academics in the sector. “GrindingHub recently declared its intention to function as an information hub, providing multiple opportunities for sharing knowledge.”

As an international platform, GrindingHub 2022 will cover all grinding technology and superfinishing processes. The organizer VDW, in cooperation with Messe Stuttgart and Swissmem, is creating the necessary framework for this. Grinding machines, tool grinding machines and abrasives are the main focus – accompanied by software solutions, automation offerings and related services.

Body text around 9,000 characters, including blanks

Author: Dag Heidecker, daxTR – Technik + Redaktion, Wermelskirchen

((INFO BOX))

Hybrid processes for rapid creation of digital twins

Hybrid manufacturing workflows also make it easier to link machining-related information and data. “Such networking is helpful when it comes to creating digital twins of manufacturing processes and of the component itself in order to improve the effectiveness of the models and simulations and to optimize both the process control and the tools,” explains Prof. Eckart Uhlmann from the Fraunhofer Institute for Production Systems and Design Technology (IPK) in Berlin. “In addition to highly specialized machines for combination machining, there is an increasing focus on universal solutions aimed, for example, at turning conventional grinding machines into combination machines through the use of hybrid tools. In hybrid machining operations, the process data and its automated interpretation are essential for defining the process control for each individual machining step, based on the initial state in each case.”