Supply bottlenecks holding back metalforming production

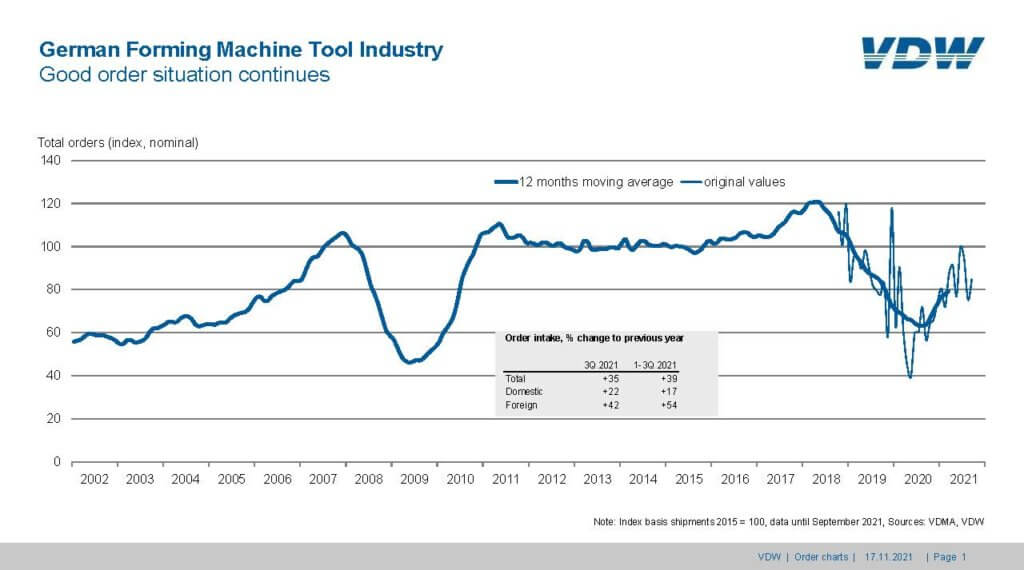

In the third quarter of 2021, order intake in the German metalforming sector increased by 35 percent compared with the prior-year period. Domestic orders increased by 22 percent. Foreign orders were 42 percent higher than a year earlier. In the first three quarters of the current year, orders from German manufacturers increased by 39 percent.

Supply bottlenecks holding back metalforming production

Growth not expected until next year in some areas

Frankfurt am Main, 25 November 2021. – In the third quarter of 2021, order intake in the German metalforming sector increased by 35 percent compared with the prior-year period. Domestic orders increased by 22 percent. Foreign orders were 42 percent higher than a year earlier. In the first three quarters of the current year, orders from German manufacturers increased by 39 percent. Domestic orders were 17 percent higher than a year earlier, while foreign orders were 54 percent higher.

“The levels of orders on hand are good. However, supply bottlenecks and sharp rises in the price of raw materials and components are increasingly holding back business,” says Dr. Wilfried Schäfer, Executive Director of the VDW (German Machine Tool Builders’ Association), Frankfurt am Main, commenting on the result. “Orders are expected to continue rising in the coming months. They are being driven by catch-up effects that will continue for quite some time,” Schäfer adds. However, it may not always be possible to translate the orders into sales as desired, as the machines can only be delivered with delays due to a lack of parts, especially electronic components. “And that is why we are having to scale this year’s summer forecast of 8 percent growth down to 5 percent,” Schäfer concedes. Double-digit growth is expected, by contrast, in the coming year.

Even in comparison with the pre-crisis year 2019, which is generally considered to be more meaningful for assessing the current situation, forming technology orders are slowly catching up. Nevertheless, the figures for the first nine months are still 4 percent lower than for the same period in 2019. The domestic market is even 20 percent lower. “The all-important automotive industry is suffering particularly from the chip shortage in Germany and is therefore cutting back on investment,” explains Schäfer. The main driving force is foreign orders, where an increase of 7 percent was posted.

The good situation is ensuring that capacities are filling up noticeably throughout the industry. This was 86 percent in October compared to 71 percent as the average for last year. Employment, a delayed indicator of economic development, has not yet bottomed out. This September it was 8.5 percent below last year’s figure of 63,300 employees. At the same time, 46 percent of companies reported a considerable shortage of skilled workers in a recent VDMA survey. There is currently a shift in demand towards more electronics-based skills.

“All in all, our industry considers itself well on the way towards overcoming the crisis. We expect supply chains to stabilize again in the coming year. Our industry will then be able to continue its recovery,” says Schäfer in conclusion.

Background

The German machine tool industry ranks among the five largest specialist groupings in the mechanical engineering sector. It provides production technology for metalworking applications in all branches of industry, and makes a crucial contribution towards innovation and enhanced productivity in the industrial sector as a whole. Due to its absolutely key role for industrial production, its development is an important indicator for the economic dynamism of the industrial sector as such. In 2020, with an average of 70,000 employees (firms with more than 50 staff), the sector produced machines and services worth around 12.2 billion euros.

Picture:

Dr. Wilfried Schäfer, Executive Director of the VDW (German Machine Tool Builders’ Association), Frankfurt am Main

Graphic: Order bookings in the German machine tool industry

You will also find graphics and pictures online under www.vdw.de in the Press section. You can also visit the VDW on our social media channels

www.youtube.com/metaltradefair

www.linkedin.com/company/vdw-frankfurt