Open community driving machine tool industry forwards: umati at METAV digital

‘umati’ allows machines from different manufacturers to be linked – securely, simply and smoothly – to customers’ own digital solutions. Based on OPC UA as the “global language of production”, it considerably simplifies the connection of machine tools to production-related IT systems. The alliance (launched in 2017 by the VDW – German Machine Tool Builders’ Association) will be participating in the METAV digital from 23 to 26 March 2021. Experts will be providing a comprehensive insight into this groundbreaking initiative for the manufacturing industry.

umati (universal machine technology interface) aspires to become a globally visible community that promotes the joint marketing and use of open, OPC UA-based interface standards for machine and plant engineering. The main aim is to achieve ‘plug and work’ connectivity between machine tools and higher-level IT systems, comparable to USB interfaces in the consumer sector. OPC UA provides the technical framework for this.

It standardises and simplifies the exchange of data between users’ machines and systems. Companion Specifications, on the other hand, standardise the data models for similar machines and systems. They determine which data is exchanged. OPC UA represents a key Industry 4.0 technology because machines from different suppliers then transmit and receive the same data structures. This considerably simplifies interactions with other machines or higher-level control and planning systems. Finally, a standardised interface allows for faster implementation of customised projects.

umati’s own exhibition stand

METAV digital will feature a virtual umati stand where the community will be able to present its achievements. Interested parties will be able to monitor the machining information from the connected machine manufacturers on the basis of the real data on the central umati information stand. “The appeal of umati lies in the fact that users can experience the data connectivity directly,” explained Dr Alexander Broos, Head of Research and Technology at the VDW. “That allows the virtual exhibition stands and actual machines to be linked together via umati’s own dashboard, which can be viewed at https://umati.app. The data can be monitored live by clicking the link symbol. Visitors to the virtual fair can then follow the processing in real time.”

Both Broos and Götz Görisch from the VDW’s Research and Technology division, as well as colleagues from the Institute for Control Technology of Machine Tools and Manufacturing Systems (ISW) at the University of Stuttgart, will be available to provide in-depth information on umati and OPC UA on the central umati stand, and to answer questions and receive suggestions.

The partner companies taking part will be showcasing their own machines and solutions on various other stands around the ‘umati hub’. Interested parties can move on to the individual exhibition stands, pick up detailed information from the manufacturers, contact and communicate with the relevant partners and view the connected processing machines for themselves. Furthermore, contact details can be exchanged via the business card portal, where interaction in the form of chats or video conferences is actively encouraged.

Complete overview of machine and tool data

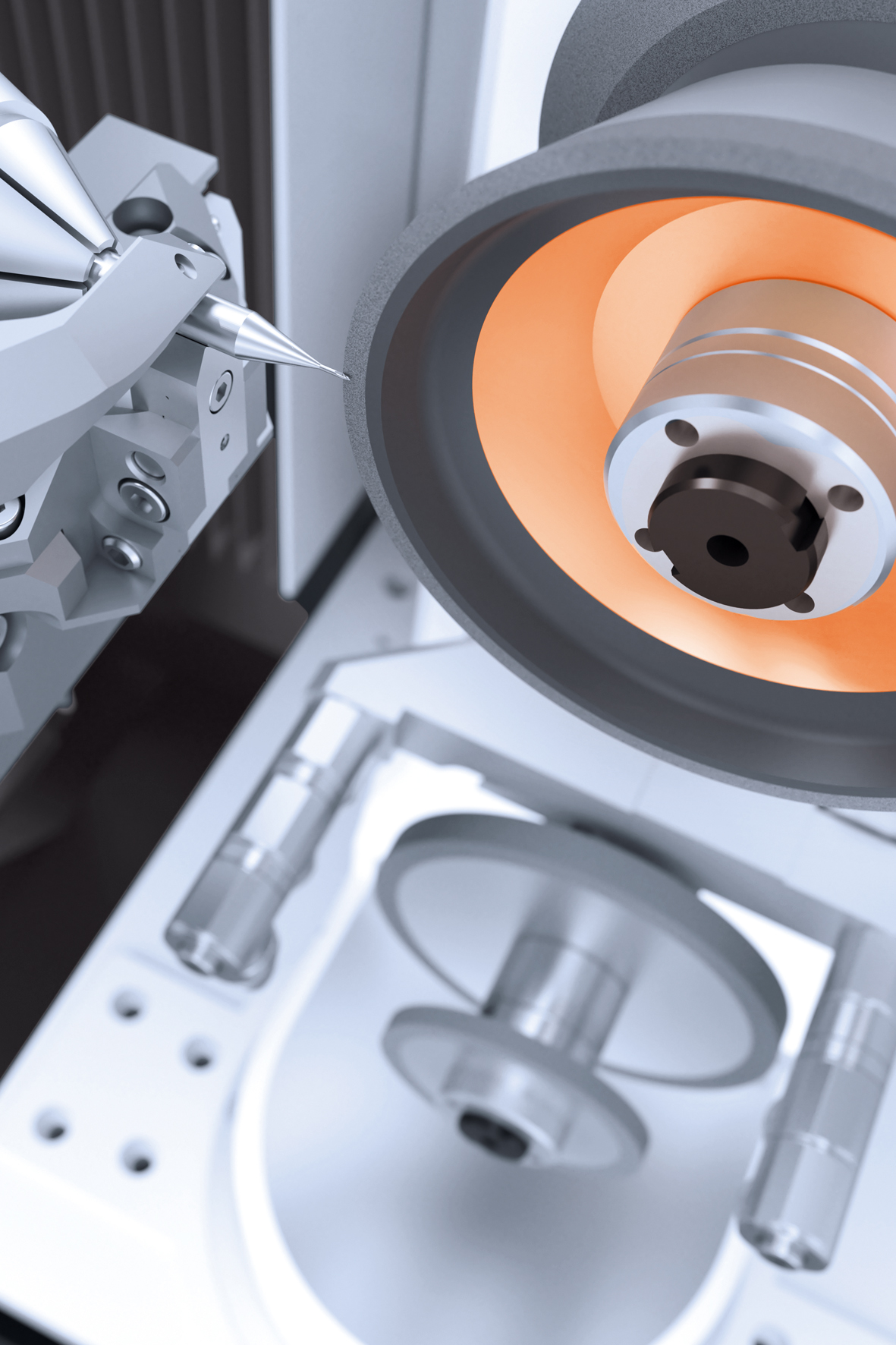

“The VDW has taken a sound and wise decision to stage the METAV as a virtual trade fair – filling a gap in the current trade fair landscape in doing so,” emphasised Dr. Stefan Brand, Managing Director of the Biberach-based Vollmer Group. “METAV digital 2021 will allow Vollmer to present its latest innovations to an international trade fair audience – despite corona. At the same time, it will demonstrate on multiple levels how important digitalisation has become for mechanical engineering. In addition to providing a virtual communication platform, it also serves as a showcase for the digital connection of machines, plants and software as the key to modern manufacturing. That is why Vollmer decided to become a umati initiative partner in 2018 and why it now collaborates closely with other mechanical engineering companies. umati guarantees that Vollmer sharpening machines can be networked with other machines regardless of the manufacturer – simply, seamlessly and securely. This gives companies a comprehensive overview of machine and tool data, enabling them not only to monitor machine conditions, but also to increase production and tool quality.”

Much easier integration of machines

Integrating machines into production systems is one of the most important trends in manufacturing right now – especially in terms of Industry 4.0. The aim is to create added value for customers from the data which then allows them to further optimise their production,” explained Günter Pumberger, Product Manager Digitalisation at Emco GmbH in Hallein, Austria. “Emco supports the development and establishment of an open industry standard for simple machine integration at the customer’s site as a means of facilitating this for all relevant partners: umati allows us to achieve this goal in a way which is time and cost-efficient for a broad customer base. The high levels of participation in cross-manufacturer standardisation mean that umati will lead to open standards ultimately being used in numerous application systems such as MES solutions in the foreseeable future. At METAV digital, people will be able to experience the considerable advantages and simplifications which this standard delivers.”

Connectivity gaining in importance

“Connectivity and the unrestricted flow of data are becoming increasingly important factors in the age of Industry 4.0. In order to equip our customers with all the necessary production tools for the future, we need an interface that enables data from a wide variety of machines and controls to be used in a wide variety of applications without the customers having to create their own individual adaptations,” reported Jürgen Kläser, Senior Manager FA / IT at Okuma Europe GmbH, based in Krefeld. “umati is helping promote the only universal machine tool data interface for Industry 4.0 that is based on the OPC UA communication standard, thus ensuring secure data transmission – both locally and to cloud platforms. We are proud to be a part of this development and to be presenting this technology at the first digital METAV.”

Benefits for umati participants

By sharing information and supporting the umati project, companies can help to promote non-proprietary communication between machine tools and processing machines and to simplify production processes as part of a strong community. Furthermore, standardised communication via corresponding OPC UA standards also enables machines from other industries to be connected and thus offer added value – benefitting not only the manufacturers, but also the customers themselves. Such uniform communication also aids the standardisation and streamlining of work processes. This can potentially yield enormous increases in efficiency and productivity. Furthermore, umati is expanding the international network of manufacturers across industry boundaries. The community can thus increase its know-how by sharing information with experts from other sectors – and open up new markets as a result. Last but not least, digital transformation relies on the secure exchange of data. umati-compliant products can help make digital factories resilient, intelligent and profitable.

More information: www.metav-digital.de

Background: umati – open community

Set up to establish open standards, umati (universal machine technology interface) is the community of the mechanical and plant engineering industry and its customers. It uses OPC UA-based interface descriptions. This forms a framework for industrial communication between machines, devices and software based on internet technologies. As a standard for data exchange, OPC UA can transport machine data but also describe it semantically in a machine-readable way.