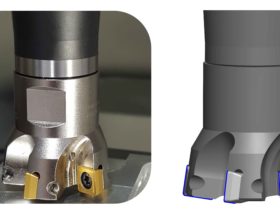

Virtual image: the digital twin

Industry 4.0, digitalised da ta in the cloud, networked processes in smart factories – what role does the metal-cutting tool play in this context? The METAV 2018 in Düsseldorf will provide practicable examples for financially viable implementation. “Just as with every real metal-cutting process the real metal-cutting tool plays an important role, the virtual tool is equally crucial for the virtual imaging of processes,” says Claudia Kleinschrodt, a research associate at the Faculty of Design Studies and CAD at Bayreuth University, where she works on the problems involved in CAD data interchange between tool models. This digital twin possesses all characteristics of the real tool and is able to image this consistently throughout all digital processes.

Consistent digitalisation, explains Claudia Kleinschrodt, “permits virtual commissioning or the simulative optimisation of process parameters, for example. Since it is possible to file all information concerning the tool at a central location, users can respond to changes in the tool during its lifetime (by regrinding, for instance), the parameters can be modified, and thus a uniformly high quality of the products be assured.” By relocating many time-intensive steps into the virtual world, moreover, processes can be designed for significantly enhanced efficiency. Automation and centralised planning, for example, lead to reduced make-ready times, better machine capacity utilisation, or optimised cycle times.

In order to obtain an overview regarding the large number of tools used in manufacturing plants, efficient tool management systems (TMSs) are indispensable. They constitute an essential precondition for automation and networking. Fully functional data interchange is important not merely for supplying the TMS with the requisite information, it is in fact crucial for each digital step in the process chain. In this context, it is not only the information content, but above all the compatibility between the highly disparate systems involved that constitutes a major challenge. Harmonised systems and high-quality data are thus crucial for implementing efficiently digitalised processes. If these conditions are met, says Claudia Kleinschrodt, “companies can benefit substantially from digitalisation of their processes. Mid-tier companies, especially, can thus operate efficiently and flexibly, and retain their long-term competitiveness.”

The digitalisation expert has high expectations for the upcoming METAV 2018 in Düsseldorf: “In regard to data interchange and virtual manufacturing, particularly, I’m primarily interested in ongoing developments relating to smart factories and commercially viable implementation of the theories developed at the research institutions concerned.”

Huge potential for optimisation

“When you hear the buzzword of Industry 4.0, what mostly comes to mind is digital factories, the internet of things, data storage in the cloud, or perhaps also robot-aided manufacturing. Metal-cutting tools are well-nigh ignored in this context,” says Thomas Funk, who is employed in the Technical Office of Emuge-Werk Richard Glimpel GmbH & Co. KG, Lauf an der Pegnitz. For the digital factory, the digital twin of the metal-cutting tool was created. This twin, says Thomas Funk, “contains all the information required for virtually imaging all stations that the tool passes through in the factory.”

For handling the resultant data volumes, efficient tool management systems are essential. Within the framework of digitalisation, process analyses will identify hidden costs at more and more mid-tier companies. Tool management systems will be used more extensively, and with the aid of the tools’ digital twins will increase still further the efficiency of the production operations involved and optimise the work sequences concerned.

“I expect the trend of recent years to continue, and the importance of digital tool data to increase still further,” comments Thomas Funk. “The demand for data is steadily rising, and therefore we shall at the METAV 2018 in Düsseldorf be showcasing our new website application, for example, on which the digital twin has been stored for many of our catalogue items for our customers, and can be downloaded free of charge.”

Metal-cutting tools are part of the process chain

The metal-cutting tool, explains Markus Kannwischer, Head of Engineering and a member of the board at Paul Horn GmbH, Tübingen, “is part of a process chain, and in contrast to almost all other production equipment is subject to wear and tear. Information on the tool has to be available in digital form in order to enable it to be used in the process chain. This applies firstly to all information on geometrical dimensions, and secondly to other information on deployment of the tool.”

Information on wear and tear, and on deployment of the tool, is important for controlling the process concerned. It can firstly be generated from the tool itself (sensorial tools). Here, the tool itself sends information on pressures, temperatures and vibrations, for instance. This information enables conclusions to be drawn on the state and stress status of the blade, and also on the stability of the process. The machining parameters can then be modified automatically using the control system, analogously to autonomous running, where the speed is matched to the boundary conditions involved. Secondly, information can be obtained at the spindle, at the machine or via separate measuring devices, which likewise enables conclusions to be drawn on the state of the blade.

A series of research projects are currently addressing the question of how the metal-cutting process can in the course of digitalisation be controlled “more intelligently”, meaning more dependably: shall useful lifetimes be utilised to the full? Is it necessary to monitor the metal-cutting process for each individual blade? “We are expecting from the METAV 2018 in Düsseldorf new findings illuminating the current status of these projects,” says Markus Kannwischer.

Nowadays, a tool has to include the relevant services

In the view of Dr. Jochen Kress, a member of the board at Mapal Dr. Kress KG, Aalen, it nowadays no longer suffices to deliver the best possible tool: “Today, a tool has to include the relevant services, like tool management and the corresponding data. We have taken this on board with our Tool Management 4.0, which we are offering on the basis of the c-Com open-cloud platform.”

With reference to the tool, he continues, the digital twin plays a particularly important role for optimising the actual machining operation. This is because it enables the entire machining cycle to be replicated in an NC simulation software package. Collisions can thus be detected, and the tool’s behaviour tested. This not only avoids the production of cost-intensive rejects, but can in many cases even replace the use of a component prototype. Above and beyond the metal-cutting process itself, the correct data on the tools facilitate all tasks encountered during a tool’s life-cycle. This applies to all processes from order placement all the way through to final disposal, such as purchasing, regrinding the tools or machine acceptance-testing at the customer’s facility.

Nowadays, in metal-cutting manufacture, more and more of the processes involving the tools required are being outsourced, like procurement, adjustment or provision. To quote Dr. Kress: “We took this development on board at an early stage, and put in place an efficient tool management system.” Only by sharing data on a joint platform like c-Com for concomitantly maximised transparency can applied technical solutions be compared inside the company. This, says Dr. Kress in conclusion, “simplifies the interaction between Purchasing and Production, and between Purchasing and the vendors”.