Focus on grinding technology: Current trends at GrindingHub 2024

Following the successful premiere of GrindingHub in May 2022, the second edition of the industry meeting place for grinding technology took place in Stuttgart from May 14 to 17, 2024. Around 500 well-known manufacturers from 31 countries presented numerous innovations along the entire grinding technology process chain at the trade fair.

As in many industrial sectors, the effects of current crises and structural challenges are also becoming apparent in the grinding industry. Against the backdrop of cost pressure and a shortage of skilled workers, approaches to resource optimization were presented by manufacturers of equipment, such as cylindrical and non-cylindrical grinding machines, tool grinding machines for cutting and machining tools, surface grinding machines, grinding, polishing, and hollowing media, as well as clamping technology, filter technology, and grinding oils. The focus was on reducing energy and raw material requirements, as well as mitigating the shortage of skilled workers through automation and digitalization. Some of the solutions and technological highlights showcased at GrindingHub are presented below.

New grinding machines and grinding concepts increase variability

Erwin Junker Maschinenfabrik GmbH from Nordrach presented grinding machines based on the newly developed Platform 3 for the first time at GrindingHub. These are grinding machines that can be flexibly adapted to their application using various configurations. A modular construction kit allows implementation of grinding machines and processes designed for various applications on a uniform basis and using as many identical parts as possible. Examples include high-speed grinding machines for machining with CBN and diamond tools or grinding machines for conventional corundum grinding processes. This not only increases cost-effectiveness, but also reduces throughput and delivery times. In addition, the increased number of identical parts increases spare parts availability. The basis is a machine bed produced as a mineral casting. Based on this, various table assemblies, guides, workpiece spindles and tailstocks that are matched to the respective application can be mounted. Up to three grinding spindles can be used. The machines are equipped with an in-process measuring system that measures the workpiece dimensions in the process and calculates correction data on this basis in order to compensate for process influences such as tool wear and temperature fluctuations. A special feature in this class is the use of an absolute measuring system for internal machine dressing. In addition, Platform 3 grinding machines come with an integrated automation concept. This includes approaches for manual loading, as well as loading by industrial robots or loading by internal and external gantry loaders.

In the field of external cylindrical grinding, the NSH Group, Chemnitz, exhibited its latest Wotan S3A model at GrindingHub. This is a compact external cylindrical grinding machine for processing small to medium-sized workpieces up to a maximum of 600 kg and a selectable center width of between 600 and 2,000 mm, depending on the version. In addition to a granite machine bed, the machine has two CNC-controlled linear axes with hydrostatic bearings in the z and x directions. In conjunction with a linear drive, they exhibit reduced wear compared to ball screw drives or recirculating roller units. Depending on accuracy requirements, the machine can be equipped with a belt-driven, direct-driven, or hydrostatic spindle. Further adaptation options relate to the integrated dressing technology, measurement technology and configuration of the grinding unit.

Rollomatic SA from Switzerland presented its new GrindSmart 630 RS machine. This is a 6-axis tool grinding machine for the production of tools up to a total length of 500 mm in a diameter range from 0.1 to 20.0 mm and a maximum groove length of 140 mm. These tools are, for example, used in medical technology in the form of bone drills operated with surgical robots. Tool handling within the machine is robot-controlled. Various configurations with and without grinding wheel changer can be implemented on the spindle side. The axes are driven by linear motors.

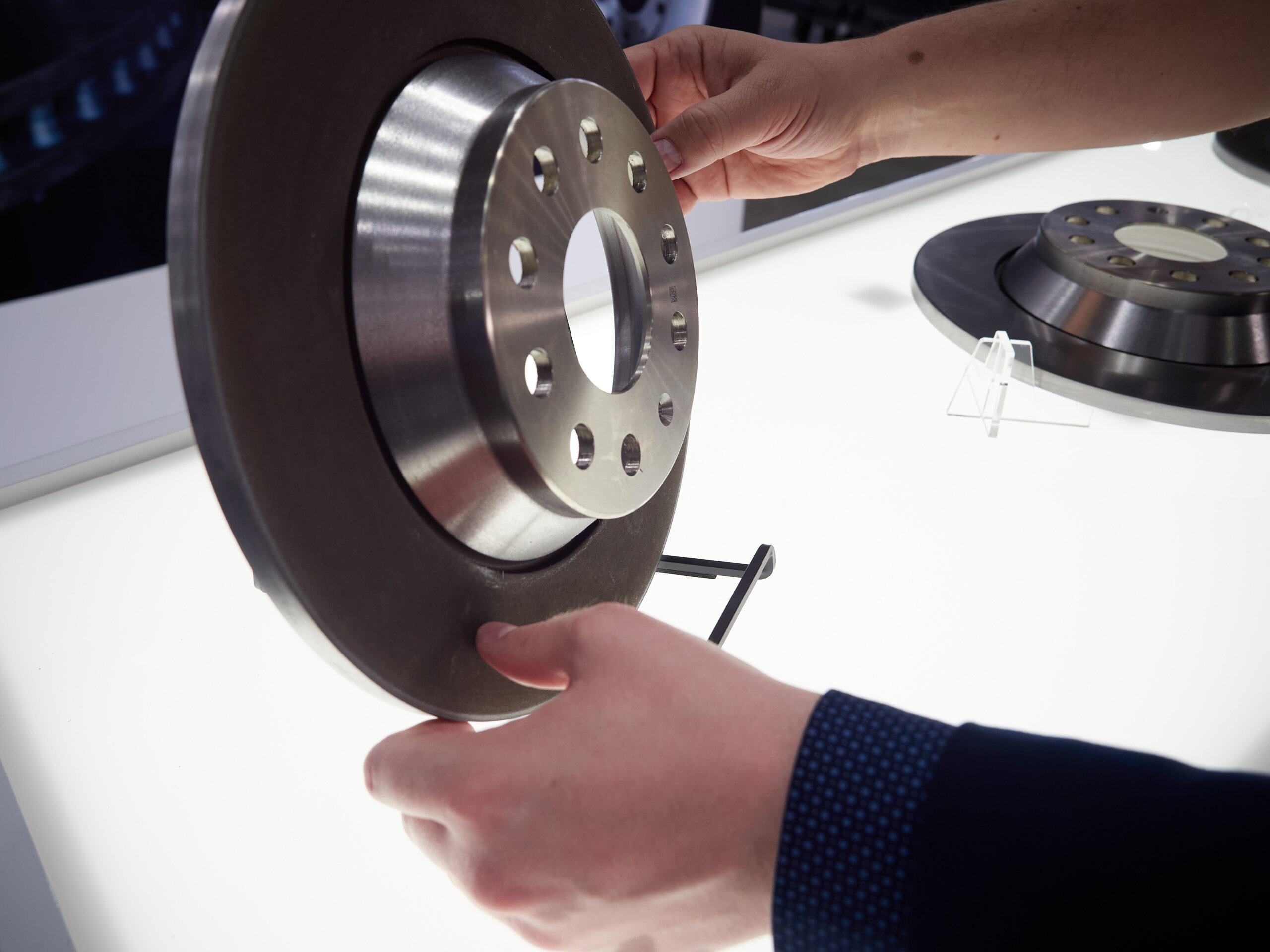

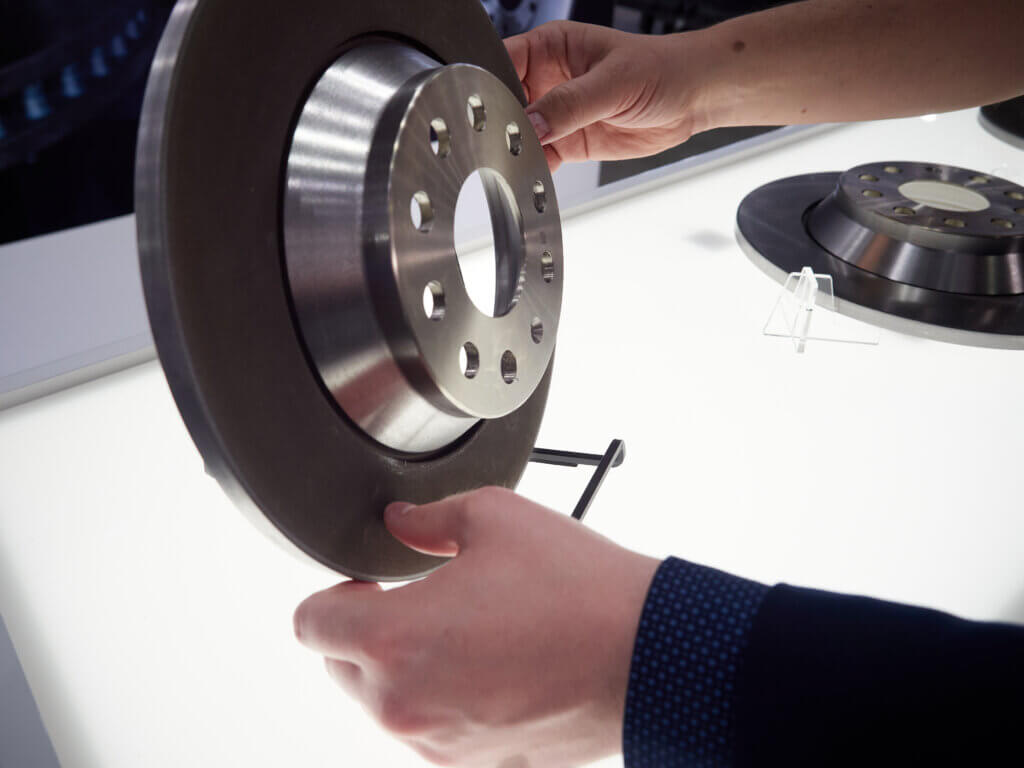

In order to reduce pollutant and particulate emissions, the Euro7 standard sets an upper limit for particulate emissions from braking systems. This is therefore a focus of current development and research projects. One approach to implementation is hard-coated brake rotors. These offer the potential to reduce abrasion by up to 90 percent. However, the hard material coating poses challenges during machining due to the relatively soft matrix with embedded carbides and the different machining behavior of the two materials. Among others, the process chain for manufacturing hard-coated brake rotors includes turning, laser coating, and grinding. These process steps result in further influencing factors that must be taken into account in the process control of the grinding process. This requires a holistic view and coordination of the process steps.

At GrindingHub, the Emag Group from Salach presented parts of the machining chain for hard-coated brake rotors, such as the VLC 450 DG, a special machine for the high-precision grinding of hard-coated brake rotors. Double-sided grinding is used here. Due to its high productivity thanks to simultaneous machining of both friction ring surfaces, high throughput, and short cycle times, the process is mainly used in brake rotor production. The cross-ground structures created perpendicular to the axis of rotation improve the tribological running-in behavior of the brake rotors compared to structures in the circumferential direction. The vertical spindle arrangement facilitates the removal of the hard material particles, while at the same time enabling good accessibility for set-up and maintenance work. The grinding tool is designed as an interchangeable ring which, thanks to its low weight of less than five kg, enables relatively easy handling when changing tools. The machine features automated loading and unloading via a feed shuttle and a workpiece lift. This allows integration into the production line.

Many smaller manufacturers also presented their products at GrindingHub. Examples include Avyac Machines from Veauche (France) and the Swiss start-up G-Elements GmbH.

Avyac showcased their 5-axis NC18 CNC drill grinding machine. This is a fully automated, compact machine concept for the production of HSS and solid carbide drills in the diameter range from 1 to 8 mm, which can optionally be extended to 14.5 mm. The maximum tool length is 320 mm. A circular loader allows up to 90 tools to be used, which are loaded and unloaded using gravity thanks to a special design. Diamond or CBN grinding wheels with a diameter of 100 mm are used. The integrated measuring sensor enables the cutting edges to be scanned, which in turn allows the cutting position to be determined for tool regrinding processes.

New software solutions allow simplified process design and planning

In addition to tool grinding machines, numerous software developments for process planning and design were also presented. One example is the implementation of power skiving tools in the SIGSpro software from Alfred H. Schütte GmbH & Co. By entering the workpiece, grinding wheel, and technology data, this enables the automated generation of CNC programs that can be transferred to the machine control and processed there. Power skiving is an alternative process for the production of gears. The tool and workpiece axes are arranged at an angle to each other. As a result of the positioning of the tool, a defined axial feed, and the coupled speed of the tool and workpiece, a relative movement occurs, whereby the tooth space is peeled out of the tool along the main cutting direction. The advantages of this process are the production of external and internal gears, a small run-out, and the production of different gears in a single clamping process.

Two start-ups, Ai-omatic solutions GmbH from Hamburg and Tetralytix GmbH from Hanover, presented their software solutions for optimizing production processes. The Toolyzer software from Teralytix enables the analysis and evaluation of any tool geometries and machining processes. In addition to predictions of process forces, torque, and power, critical meshing conditions can also be detected and workpiece quality predicted. Among other things, this offers the potential to shorten development times and save costs. Another way to minimize expenses in the production process is to ensure a stable production process and avoid machine downtime. The company ai-omatic has developed software for this purpose that uses probabilistic models to provide an alternative to conventional maintenance approaches. To this end, the condition of the machines is detected in real time, and predictions are made about the maintenance requirements of the machine systems based on various integrable data sources.

A holistic view of the grinding machine and peripherals enables efficient process control

A capable grinding machine is not the only decisive factor in the production of high-quality workpieces. The design of an efficient and resource-optimized grinding process requires a holistic view of the grinding machine in conjunction with its peripherals. When it comes to lubricant supply, for example, a distinction can be made between the lubricant itself, corresponding supply strategies, and the filtering and reprocessing of lubricants after the grinding process. Numerous companies presented their products from these areas at GrindingHub. These include Oelheld GmbH from Stuttgart, Carl Bechem GmbH from Hagen, the Swiss company Blaser Swisslube AG and Knoll Maschinenbau GmbH from Bad Saulgau.

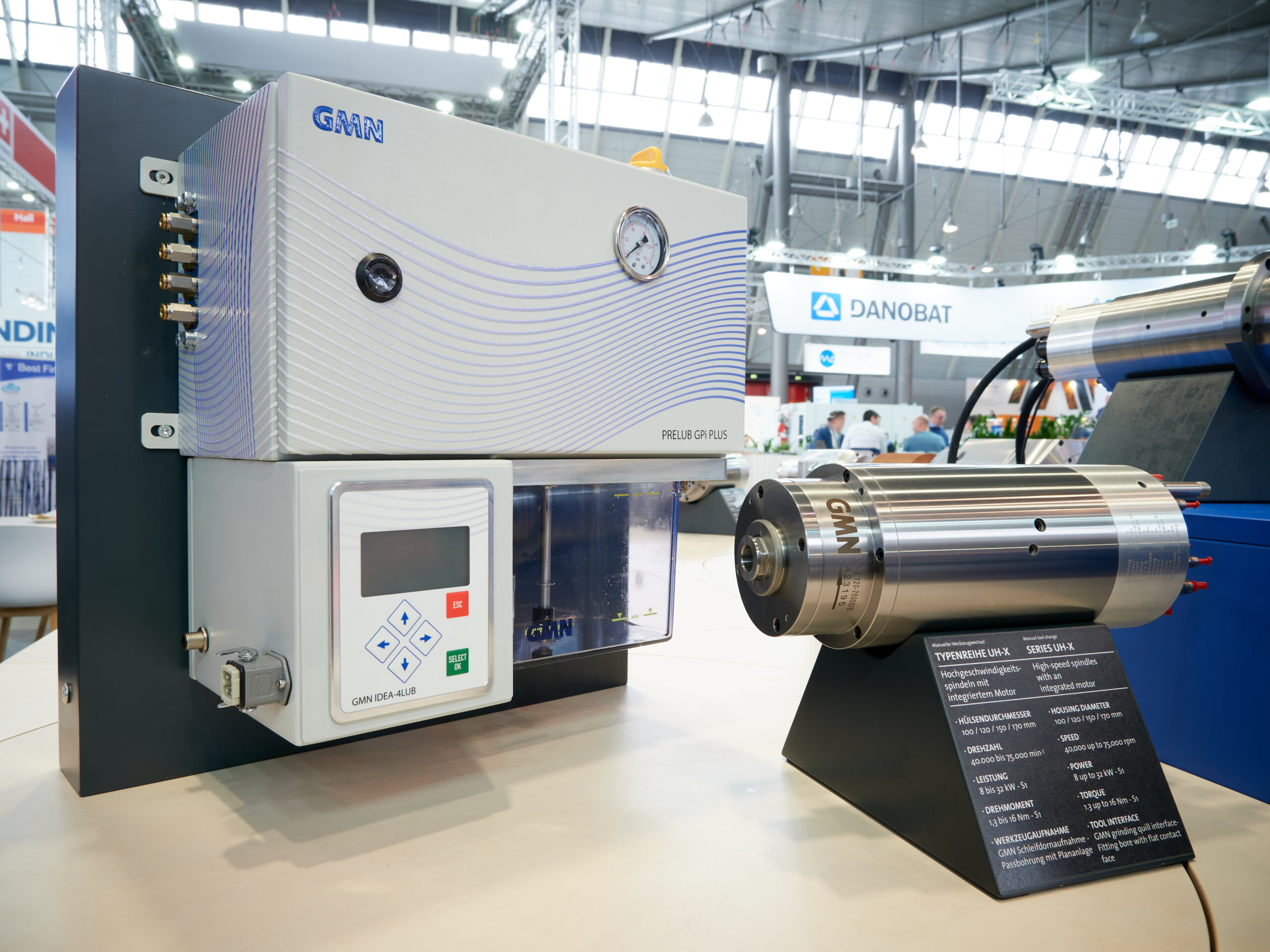

The spindle is an important component of all machine tools and grinding machines. GMN from Nuremberg, for example, presented its new UH spindle series for internal and external cylindrical grinding processes. It is characterized by significant optimizations of key performance features across all versions. For the first time, GMN is using synchronous motors with a maximum output of 32 kW and speeds of up to 120,000 rpm in a series spindle. Due to the higher torque, synchronous motors use a third less installed power in most applications compared to asynchronous motors. This results in better utilization of the available power range and greater efficiency. The increased power density, combined with reduced power consumption, also results in various advantages in the design of the spindle. Larger axle holes, ball bearings, and shaft diameters in conjunction with shorter shafts result in smoother running. In addition, the potential resulting from the improved dynamic rigidity and load capacity can be exploited either through larger tool interfaces or higher maximum speeds. As the rotor heats up less, there is less thermal displacement of the shaft and less cooling is required. This reduces the amount of air and oil required by spindle.

In addition to the new spindle series, GMN also presented its new Prelub GPi Plus lubrication unit for supplying the spindle with lubricant. Like the spindle itself, it features the IloT technology “Integrated Data Evaluation and Acquisition for Spindles”, or IDEA-4S for short. During the process, the spindle provides data such as bearing and coolant temperature, speed, as well as data on vibrations and optionally also any misalignments. The machine control unit identifies the spindle using its digital type plate, reads the data relevant for lubrication, and passes it on to the lubrication unit. This allows the lubrication of the spindle to be automated and controlled as required according to preset lubrication parameters. This allows the lubrication cycle to be interrupted, which saves lubricant in the event of a spindle standstill. In addition, the available information is used to regulate venting and monitor the oil supply automatically.

The underlying IloT technology is an embedded system developed by GMN. The sensor system in the spindle continuously determines the most important process parameters, which are continuously sent bidirectionally in real time via IO-Link to the machine control system and the production networks. This allows permanent optimization of the deployment and fast reactions to undesirable developments. It also enables the comprehensive optimization of all processes, which in turn improves the efficiency of components and minimizes the consumption of resources.

In addition to the UH spindle series and the new Prelub GPi Plus generation of lubricating devices, GMN also presented its SpiOnline online calculation tool at GrindingHub. This makes it possible to select the optimum tool-spindle combination for the corresponding grinding process before actually machining. Not only is it possible to search for an optimum tool for an existing spindle, but the right spindle can also be determined for applications that require special tools. Selecting an optimum tool for example allows a specific speed range to be achieved and optimum machining results to be obtained.

Additive manufacturing processes open up new design possibilities for abrasives

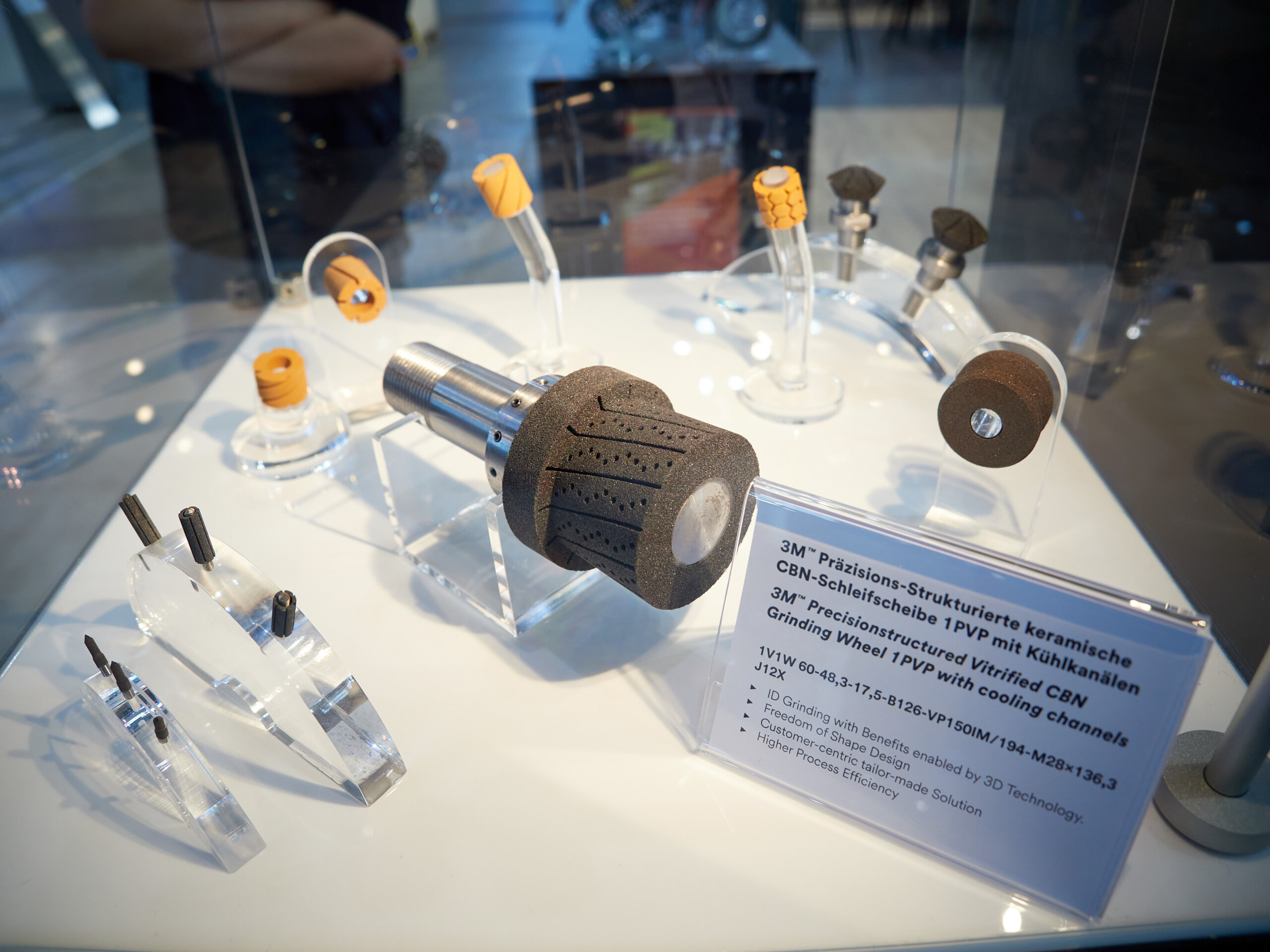

In addition to machine concepts, as well as integrated spindle and supply systems, the grinding wheel is the key element in grinding processes. It is in direct contact with the workpiece and has a major influence on the machining result and process productivity. For this reason, developments in the field of grinding wheels and their preparation for the grinding process are being driven forward on an ongoing basis.

Additive manufacturing of abrasives is currently a hot topic. The basic tool body, the grinding wheel, or both can be produced using additive manufacturing processes. Compared to conventional manufacturing processes, additive manufacturing processes allow significantly greater design freedom in terms of the components produced. In contrast to manufacturing processes with a geometrically defined cutting edge, where it is possible to supply cooling lubricant through the tool close to the point of action, this is usually associated with major challenges in grinding processes. Here, additive manufacturing processes offer the possibility to design grinding wheel systems with an internal cooling lubricant supply.

At GrindingHub, 3M presented type 1PVP structured ceramic CBN grinding wheels for internal cylindrical grinding processes. The adaptive build-up of thin layers creates 3D-printed structures. These allow greater design freedom compared to conventionally manufactured tools, as the limits of mechanical processing do not have to be taken into account. Almost any three-dimensional shapes and structures, slots, and cooling lubricant holes can be produced in this way. In addition, additively manufactured tools boast a homogeneous grain and pore distribution. The degrees of freedom in terms of design and the associated specific design for the respective application, as well as the material properties of the additively manufactured grinding tools, mean that greater efficiency and improved performance potential can be achieved compared to conventional grinding tools.

Riegger Diamantwerkzeuge GmbH from Affalterbach presented another example of current developments in the manufacture of additively manufactured grinding wheel coatings. As part of a project funded by the German Federal Ministry for Economic Affairs and Climate Action’s Central Innovation Program for SMEs (ZIM), approaches are being developed for the production of abrasive coatings for CBN and diamond wheels made of synthetic resin using digital light processing (DLP). Based on this process, individual grinding wheel profiles can be created that are only limited in their dimensions by the capabilities of the 3D printer. The benefits here are that there is no need for machined parts, manual assembly, or filling of the grinding wheel mold. This opens up potential for cost savings. Current challenges include the production of homogeneous, highly concentrated abrasive coatings and the addition of additives to optimize the bond.

In addition to new concepts for grinding wheel production, grinding wheel preparation is an important factor. Grinding wheel preparation gives the grinding wheel its final contour, while breaking the abrasive grains out of the bond exposes new abrasive particles and therefore creates the basis for grinding wheel topography. At GrindingHub, numerous manufacturers such as Cleveland from Löffingen and GWD Industrial from Austria presented conventional approaches to dressing grinding wheels, for example using SiC or diamond dressing tools. These processes for dressing grinding tools can be carried out either externally or internally and, in many cases, require a downstream sharpening process to reset the bond and increase the cutting performance of the grinding wheel.

Another approach to grinding wheel preparation is based on spark erosion processes. In the case of abrasive coatings with a conductive bond component, the bond is removed in the arc without affecting the non-conductive abrasive particles. This way, the profile geometry and surface topography of the grinding wheels are created without contact and therefore without force. Among others, the benefits of this process include the possibility of producing geometries that cannot be produced with conventional dressing processes, as well as generating a significantly increased grain protrusion. This results in a more cutting-friendly topography, which enables higher stock removal rates and longer grinding wheel service lives to be achieved. At GrindingHub, both the Japanese manufacturer Mitsubishi Electric and the company Häberle from Laichingen exhibited wire-cutting machines for preparing grinding wheels with conductive bond systems. Häberle is performing an axis extension based on a Robocut C400iC wire erosion machine from Japanese company Fanuc here in order to enable the rotary erosion of grinding wheels. Häberle presented a solution for the automated dressing of grinding wheels under the product name Häberle Robocut Plus-Big-R. In conjunction with a large robot cell with the Fanuc M20 robot, new workpieces are stored and the Häberle Robocut 400 ROT 6-axis robot is automatically loaded and unloaded. The cell can be loaded with new workpieces in parallel to production using a set-up station.

Automation increases productivity and provides answers to the shortage of skilled workers

In addition, a wide range of manufacturers presented numerous other automation techniques/approaches for a wide variety of processes. Häberle also presented an approach for feeding raw parts as bulk material at GrindingHub. These are fed unsorted via a conveyor belt into the work area of a robot. Camera-based systems are used to record the orientation of the components, evaluate this information, and pass it on to the robot. Based on the position information, the robot picks up the components from the conveyor belt and places them into their clamping device. The conveyor belt performs jogging movements to change the position of the components on the conveyor belt and to enable the robot to grip all components. This eliminates the need for further mechanical process steps to produce a suitable component orientation.

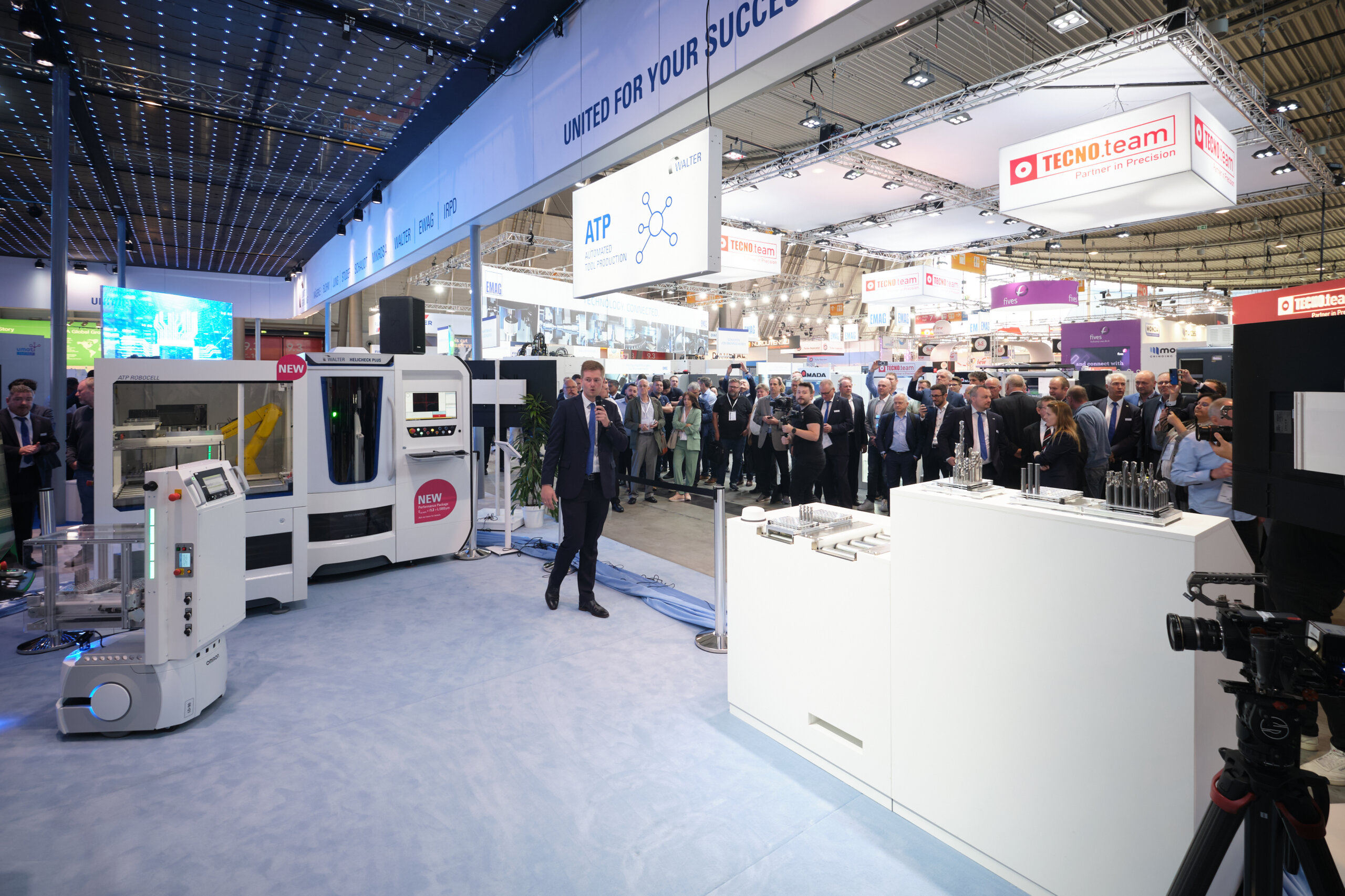

On the stand of the United Grinding Group from Bern (Switzerland), the “ATP – Automated Tool Production” – an automation solution for cylindrical precision tools by Walter Maschinenbau GmbH from Tübingen was presented. It consists of at least one robot cell accessible from the front for the automatic loading and unloading of the machines and at least one autonomous, mobile robot for transporting the tool pallets or individual parts between the processing and storage stations. The system can be integrated into existing system layouts and is suitable for all grinding, measuring, and eroding machines from Walter. It can also serve as an interface to machines from other manufacturers. The transport robot removes the pallet or individual part from the transfer station of the respective machine and transports it to its corresponding destination. A control system for higher-level data and process control, as well as a standardized communication model are used for this purpose.

Automation solutions of this kind are one approach to countering the shortage of skilled workers, while increasing productivity. Automating processes offers potential to maintain and scale manufacturing processes with less dependence on the available workforce – particularly in the areas of workpiece handling within the processing machine, as well as loading/unloading and equipping of machines.

High-performance cutting tools thanks to edge and surface modification

Edge and surface modification represents an important step in the manufacture of tools with geometrically defined cutting edges. There are many reasons for such modifications, but they are mainly aimed at improving the behavior during use and increasing the service life of the cutting tools. A distinction is made between processes for preparing cutting edges and those for surface modification of functional surfaces. Functional surface modification is often carried out after a grinding process to improve the adhesion of the coating for the coating process or after the coating process as part of a post-coating treatment. Post-coating treatment is carried out to reduce surface defects such as droplets and thereby improve the surface quality. The surface quality of the cutting faces can influence chip removal, and thereby also process reliability and tool life, particularly in drilling or deep drilling processes. The cutting edges are often prepared by rounding. This serves to reduce possible defects in the area of the sharp edges and to increase edge stability. The result is a positive effect on the wear behavior of the tools and an increase in their service life.

One approach to surface treatment and cutting edge preparation is the use of barrel finishing processes. Stream finishing technology is a new process. Rotating workpieces are lowered into a rotating container filled with abrasive or polishing agent. These processes offer the advantage that even small geometries can be fully processed. Based on this technology, Australian manufacturer Anca presented its new stream finishing EPX-SF at GrindingHub. This is a machine for cutting edge preparation and surface modification that can be integrated into automated cells. It has three spindles and eleven axes. It is able to reduce the edge roughness to less than 100 nm and adjust the edge radii to a few micrometers with a controllable K-factor. In conjunction with the fully automatic loading system, the automation enables up to 1,800 tools per day to be prepared and modified. The machine is also equipped with a tool cleaning station and process monitoring systems. This is intended to ensure consistent tool quality by continuously adjusting the media level.

In addition to this new process, conventional methods for rounding cutting edges such as brushing were also demonstrated. Swiss company Dynamic Finishing is showcasing a solution for the industrial production of defined cutting edge shapes and surfaces that can be integrated into the grinding machine. The brushing process is implemented on the grinding machine.

GDS from Ofterdingen takes a different approach. A robot-controlled brushing process for targeted cutting edge rounding of shank tools and indexable inserts is presented here. This is a robot cell with the name Magicedge. In basic terms, a robot is used to brush the tool in a targeted manner. The robot kinematics influence the shape, size, and course of the cutting edge rounding. In contrast to barrel finishing, brushing processes allow the cutting edges and areas close to the cutting edges to be prepared without affecting distant areas. Further customer-specific requirements, such as pick and place, glass bead blasting, quality assurance, and polishing can be implemented in the robot cell.

A similar process was presented by Nagel from Nürtingen in cooperation with Bruker Alicona from Austria under the name NaPrep. A tool is also prepared robotically here. The individual edges are selectively prepared using coated processing brushes. This is followed by an optional polishing process. The automated process enables flexibility in terms of tool types thanks to a gripper station. as well as unmanned operation of the system. Integrating a measuring system allows in-process measurement of the tools to be performed, which enables self-regulating process parameter adjustment – a closed loop. An EdgeMaster from Bruker Alicona is used to measure the shape of the cutting edge here. This is an optical measuring device which, based on focus variation and in conjunction with corresponding evaluation software, enables both detection and measurement of cutting edges and their shapes.

Targeted process and component control using suitable measuring systems

In-process and post-process measurements are required in order to record and evaluate the machining results of manufacturing processes. In addition to measuring technology for recording process forces or process behavior, measuring systems are used in particular for determining dimensions, position, and shape, as well as for analyzing surface properties.

In addition to the concept for cutting edge preparation, Bruker Alicona presented its new FocusX optical measuring device at GrindingHub. The non-contact measurement offered by optical measuring devices is one of the key advantages over tactile measuring devices, as it is also suitable for analyzing sensitive components. For example, any risk of the surface of components used in medical technology being altered must be ruled out by the measuring process. FocusX uses the Advanced Focus Variation, which was first introduced with the µCMM optical measuring device. Not only is this faster than the previous Focus Variation technology, it is also particularly suitable for smooth surfaces. However, complex shapes, small radii, acute angles, and steep flanks up to bores with a diameter-to-depth ratio of 1:3 to 1:10 can also be detected. Rotating and tilting axes allow components to be measured from different angles and assembled into a 3D image using appropriate software integration. ISO-compliant roughness measurements can also be performed.

External measuring systems offer various advantages over internal machine measuring systems. For example, use parallel to the main time or controlled measurement conditions can be implemented more easily. In many cases, however, measurement on the processing machine can also be an effective approach. One example of this is the Laser Contour Check, which Walter integrates into its grinding and eroding machines. This allows various tool parameters on cylindrical tools to be measured without contact and, if necessary, automatic correction of the tool diameter and tool profile to be implemented in the process.

Special exhibition areas enable networking between research and science, start-ups and industry

Various research institutes from the field of production technology presented the results of current research projects in the GrindingSolutionPark. Two projects from the Manufacturing Technology Institute (MIT) in Aachen are good examples of this. As part of a research project on the “Analysis of tribological conditions when grinding polycrystalline diamond (PCD) with a water-mixed cooling lubricant”, a wide variety of application tests are used to determine parameters that are then in turn used to develop mathematical friction laws for single-grain and multi-grain contact and for numerical simulation of the thermo-mechanical load collective. In a subsequent step, an explanatory model for the grinding of PCD with a water-mixed cooling lubricant is derived from this. The second project focuses on “Investigations of thermo-mechanical-chemical stresses during external circumferential cross-grinding of 100Cr6”. This material is frequently used in roller bearings, which are subject to ever stricter requirements due to the shift toward electromobility. Based on testing performed to date, targeted process control of the grinding process should support the formation of an initial boundary layer on the bearing surfaces. The aim is to increase wear protection and reduce the amount of running-in previously required to form an additive-induced wear protection layer. The Institute for Production Engineering and Machine Tools (IFW) from Hanover presented “Analysis methods in the production of grinding tools”. Bending tests, hardness measurements, phase analyses, density measurements, surface topography images, single grain scratch and shear tests, as well as scanning electron microscopic examinations are for example performed in the area of bonding, grain and pore characterization here. The project “In-situ assessment of residual stress state in gear grinding process: An Artificial Intelligence Approach” of the IWF in Berlin describes an approach for assessing residual stresses in components based on Industry 4.0 methods. To this end, grinding processes are carried out with in-process measurement technology, followed by residual stress measurements. The data collected serves as input variables for an AI network. This way, it should be possible to make predictions about the residual stress state in subsequent grinding processes without having to carry out new residual stress measurements. The Institute of Machining Technology (ISF) in Dortmund presented current “Grinding technology developments in the additive-subtractive process chain”. The possibilities of the frequently necessary post-processing of additively printed components by grinding, microfinishing, and wet blasting are discussed, while approaches for targeted process control of the respective processes for the post-processing of additively printed components are developed here.

Young companies showcased their expertise and services at the Startup Hub. Weber Technologies from Potsdam presented diamond coatings for precision carbide tools. WT-DIA diamond coatings are used for machining various materials, such as CFK, GFK, CFK/Al sandwich material, ceramics, graphite and Al alloy materials, and potentially improve the performance of the tools. Coating is carried out using the hot-wire CVD process. Process gases are introduced into the coating chamber in a vacuum and decomposed at a high temperature. Released carbon atoms accumulate on the substrate surface, so that a crystalline diamond layer grows during the coating process. The layer can be built up in the microcrystalline and nanocrystalline range, as well as with a graded structure in a thickness of 3 to 20 µm.

Meeting current challenges with innovations

GrindingHub 2024 focused in particular on automation and digitalization of manufacturing processes. After all, these can help counteract the current shortage of skilled workers, while at the same time increasing productivity. Numerous detailed improvements to increase the efficiency of various components, their peripherals, and the grinding tools used were demonstrated as a way of counteracting the issues associated with the shortage of skilled workers, cost pressure, and a desire to create sustainable processes and products. Examples of this include additively printed grinding tools and efficiency improvements in spindle technology.

Grinding technology processes are extremely important in the context of the transition to more eco-friendly modes of transport and the goal of eventually achieving emission-neutral mobility. In addition to new drive concepts, the focus will also be on low-emission brake systems and their production. The grinding of hard-coated brake rotors is a growing sector that requires extensive innovations in terms of grinding machines, grinding tools, and process control.

Author: Ulf Hensler, M.Sc., Institute of Machining Technology, Dortmund University of Technology, e-mail ulf.hensler@tu-dortmund.de

Downloads

Pictures

Picture 1 Advanced Focus Variation also enables optical measurement of highly reflective surfaces.

Picture 2 Increased efficiency thanks to new generations of spindle technology and machine peripherals.

Picture 3 The production of hard-coated brake rotors requires innovative solutions in the process chain.

Picture 4 Extended design options and increased performance potential of abrasives through additive manufacturing.

Picture 5 Automation techniques offer the potential to increase productivity and counter the shortage of skilled workers.

Picture 6 Software solutions enable more efficient production of complex cutting tools.